Low Machining Parameters Produce High Cutting Performance when Machining AISI 1045 at Dry Cutting Conditions Using a CNC Lathe Machine

Downloads

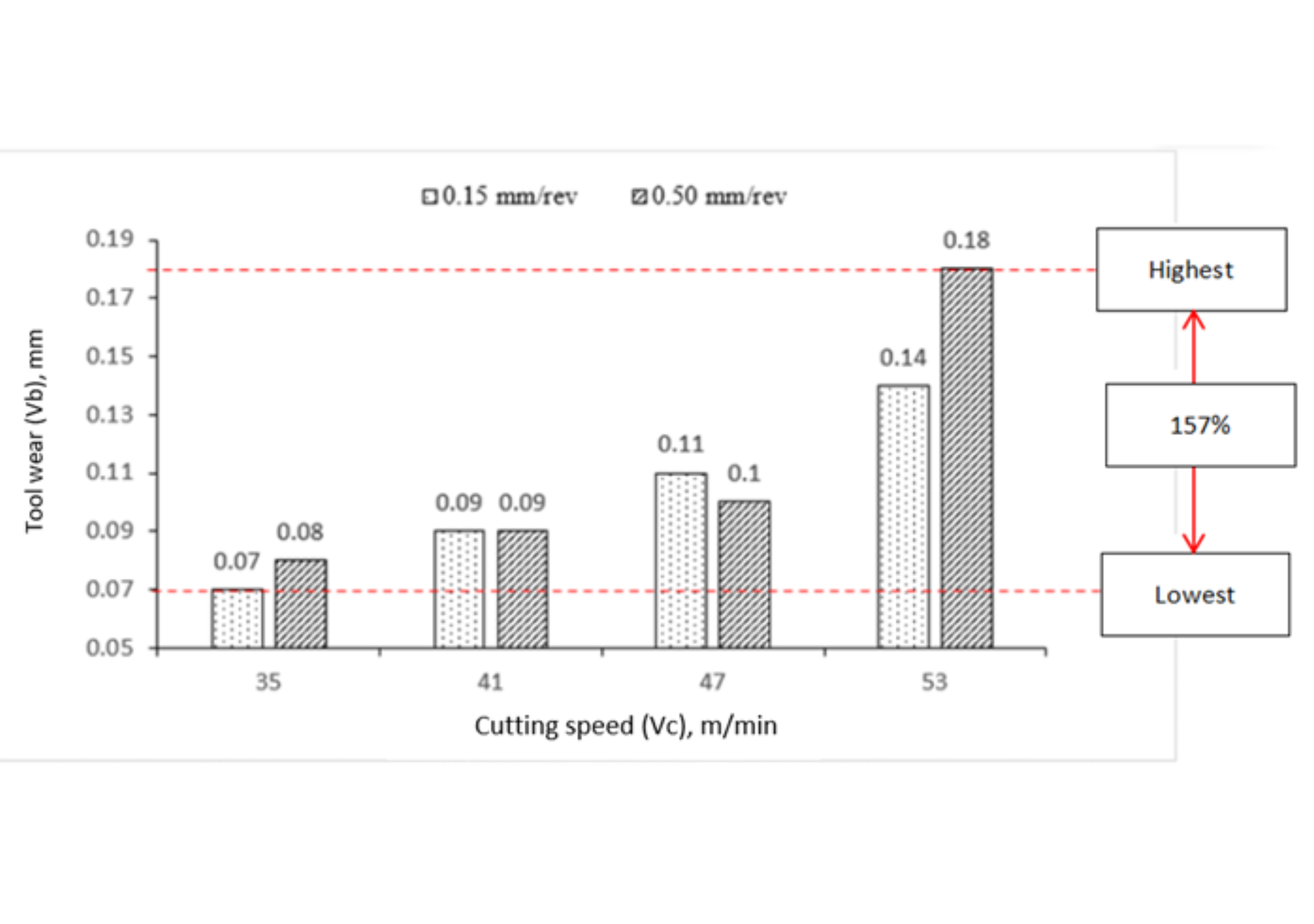

AISI 1045 medium-carbon steel is widely used for machining because of its excellent machinability. It balances strength and workability in various manufacturing applications, including machinery parts, gears, mold pins, automotive parts, crankshafts, bolts, and studs. The most significant disadvantage of AISI 1045 machining is that if the cutting parameters are not managed appropriately, it can affect the efficiency of the machining process, which involves tool life and product surface finish at dry cutting conditions. This study aims to determine suitable cutting parameters for AISI 1045, identify the optimum minimum tool wear (VB), and assess surface roughness (Ra). This study used various machining parameters at a cutting speed (Vc) of 35–53 m/min, feed rate (fr) of 0.15, and 0.5 mm/rev at a 1 mm constant depth of cut (DOC). The results showed that a Vc of 35 m/min and a fr of 0.15 mm/rev obtained the lowest average VB of 0.07 mm and Ra of 3.8 µm. This study found that low machining parameters produce high dry-cutting performance. This study provides guidelines for machinists to use appropriate cutting parameters when machining AISI 1045 under dry-cutting conditions at short machining times. In addition, it promotes sustainable machining and prevents air pollution from using coolants (chemical reactions).

Abbas A. T., Al Bahkali, E. A., Alqahtani, S. M., Abdelnasser, E., Naeim, N., & Elkaseer, A. 2021. Fundamental investigation into tool wear and surface quality in high-speed machining of Ti6Al4V alloy. Materials (Basel), 14 (7128), 1–19.

Abbas, A. T., Benyahia, F., El Rayes, M. M., Pruncu, C., Taha, M. A., & Hegab, H. 2019. Towards optimization of machining performance and sustainability aspects when turning AISI 1045 steel under different cooling and lubrication strategies. Materials (Basel), 12 (3023), 1–17.

Afif, I. Y., Jamari, J., Saputra, E., Saefudin, S., Subri, M., & Amin, M. 2024. Exploring wear characteristics of AISI 1045 steel under variable disc rotation speeds: a tribological investigation. Teknik, 45 (1), 111–116. doi: 10.14710/teknik.v45i1.59720.

Azhar, A. A., Azlan U. A. A., Bakar,H. A., Tamin, N., Herawan, S. G., & Ahmad, Z. 2020. Friction comparison and wear analysis of ceramic cutting tools made from alumina-zirconia-chromia content. Journal of Advanced Research in Applied Mechanics, 112 (1), 175–182.

Bakar, H., Fahmi, N., Mokhtar, F., Tamin, N., Azlan, U., Adam, A.A., Izamshah, R., & Kasim, S. 2018. Fabrication and Machining Performance of Powder Compacted Alumina-Based Cutting Tool. MATEC Web Conferences, 150, 2–6, doi: 10.1051/matecconf/201815004009.

Budiman, A. Y., & Mohruni, A. S. 2020. A review on thin-walled cryogenic machining on inconel or aerospace materials. Journal of Mechanical Science and Engineering, 7 (1), 001–005.

Faiz, M. M., Hairizal, M., Naim, M. F., Norfauzi, T., Umar, U. A.A., Aziz, A. A., & Noorazizi, S.M. M. 2019. Effect of hydraulic pressure on hardness, density, tool wear and surface roughness in the fabrication of alumina-based cutting tool. Journal of Advance Manufacturing Technology, 13 (1), 23–37.

Guo, X., Zhu, Z., Ekevad, M., Bao, X., & Cao, P. 2017. The cutting performance of Al 2 O 3 and Si 3 N 4 ceramic cutting tools in the milling plywood. Advances in Applied Ceramics, 6753 (9), 1–8.

Gurbuz, H., & Gonulacar, Y. E. 2020. Optimization and evaluation of dry and minimum quantity lubricating methods on machinability of AISI 4140 using Taguchi design and ANOVA. Proceeding of Mechanical Engineering Scince, 1–17. doi: 10.1177/0954406220939609.

Hatta, W. N., Jafar, F. A., Nor, F. M., & Noor, A. Z. M. 2019. Machinability performance of CNC turning based on automated coolant supply system. International Journal of Innovative Technology and Exploring Engineering, 8 (10), 3953–3957.

Iqbal, A., Zhao, G., Cheok, Q., He, N., & Nauman, M. M. 2022. Sustainable machining: tool life criterion based on work surface quality. Processes, 10 (6), 1087.

Hua, Y., & Liu, Z. 2019. Effects of Machining Induced Residual Shear and Normal Stresses on Fatigue Life and Stress Intensity Factor of Inconel 718. Applied Sciences, 9 (4750), 1–17.

Javier, F., Vilches, T., Mart, S., Gamboa,C. B., Herrera, M., & Hurtado, L. S. 2021. Influence of tool wear on form deviations in dry machining. Metals (Basel)., 11 (958), 1–22.

Ji, W., & Wang, L. 2019. Industrial robotic machining: a review. International Journal of Advanced Manufacturing Technology, 103 (1–4), 1239–1255.

Jiang, Z., Gao, D., Lu, Y., & Shang, Z. 2020. Optimisation of cutting parameters for minimising carbon emissions and cost in the turning process. Journal of Mechanical Engineering and Sciences, pp. 1–13.

Jose, D. A., Antonio, D. Á., Migu, H., & Cantero, L. 2018. Finishing turning of ni superalloy haynes 282. Metals (Basel), 8 (843), 1–12. doi: 10.3390/met8100843.

Kaladhar, M. 2020. Optimization of machining parameters when machining beyond recommended cutting speed. World Journal of Engineering, 17 (5), 739–749. doi: 10.1108/wje-01-2020-0018.

Martins, A. M., Oliveira, D. A., Magalhães, F. C., & Abrão, A. M. 2023. Relationship between surface characteristics and the fatigue life of deep rolled AISI 4140 steel. International Journal of Advanced Manufacturing Technology, 129 (3–4), 1127–1143.

Norfauzi, T., Hamid, A., Azlan, U. A. A., & Ali, M. B. 2024. Optimising cutting parameters of aisi h13 to reduce tool wear and surface roughness in the lathe cnc machining process. Journal of Advanced Manufacturing Technology (JAMT), 18 (3), 15–18. doi: 10.1201/9781482278804-7.

Peksen, H., & Kalyon, A. 2021. Optimization and measurement of flank wear and surface roughness via Taguchi-based grey relational analysis. Materials Manufacturing Process, 1–10. doi: 10.1080/10426914.2021.1926497.

Rabinovich, G. F., Gershman, I. S., Yamamoto, K., & Dosbaeva, J. 2020. Effect of the adaptive response on the wear behavior of PVD and CVD coated cutting tools during machining with built-up edge formation. Nanomaterials, 10 (2489), 1–22.

Saifuldin, M., Mokhtar, M., Yusoff, A. R., & Lubis, M. S. Y. 2024. Effect of machining parameters on micro-burrs formation of aluminium puncher using high-speed machining process. Journal of Advanced Research in Applied Mechanics, 1 (1), 47–60.

Salur, E., Kuntoğlu, M., Aslan, A., and Pimenov, D. Y. 2021. The effects of MQL and dry environments on tool wear, cutting temperature, and power consumption during end milling of AISI 1040 steel. Metals (Basel)., 11 (1674), 1–17.

Sandin, O., Prieto, J. M. R., Hammarberg, S., & Casellas, D. 2023. Numerical modelling of shear cutting using particle methods. IOP Conference Series: Materials Science and Engineering, 1284 (1), 012048. doi: 10.1088/1757-899x/1284/1/012048.

Suresh, P., & Poongodi, T. 2018. Evaluation of surface roughness during turning of Al-SiC and Al-SiC-Gr composites. Multidiscip. Model. Mater. Struct., 14 (5), 874–890.

Tamin, N. F., Azlan, U. A. A., Remle, N. S., & Osman, M. H. 2017. Study on surface integrity of AISI 1045 carbon steel when machined by carbide cutting tool. MATEC Web Conferences, 01075 (97), 2–6. doi: 10.1051/matecconf/20179701075.

Wei, W., Li, Y., Xu, Y., & Yang, C. 2021. Research on tool wear factors for milling wood-plastic composites based on response surface methodology. Bioresources, 16 (2008), 151–162.

Yang, Q., & Ming, W. 2025. Review: application of green manufacturing processes in precision machining of automotive components. Green Manufacturing Open, 3(1), 3-10. doi: 10.20517/gmo.2024.120501.

Zhou, T., He, L., Wu, J., Du, F., & Zou, Z. 2019. Prediction of surface roughness of 304 stainless steel and multi-objective optimisation of cutting parameters based on GA-GBRT. Applied Sciences, 9 (3684), 1–22.

Copyright (c) 2025 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.