Facile and Environmentally Friendly Synthesis of Low-defect Few-Layers Graphene (FLG) Using Combined Shear Exfoliation Methods

Downloads

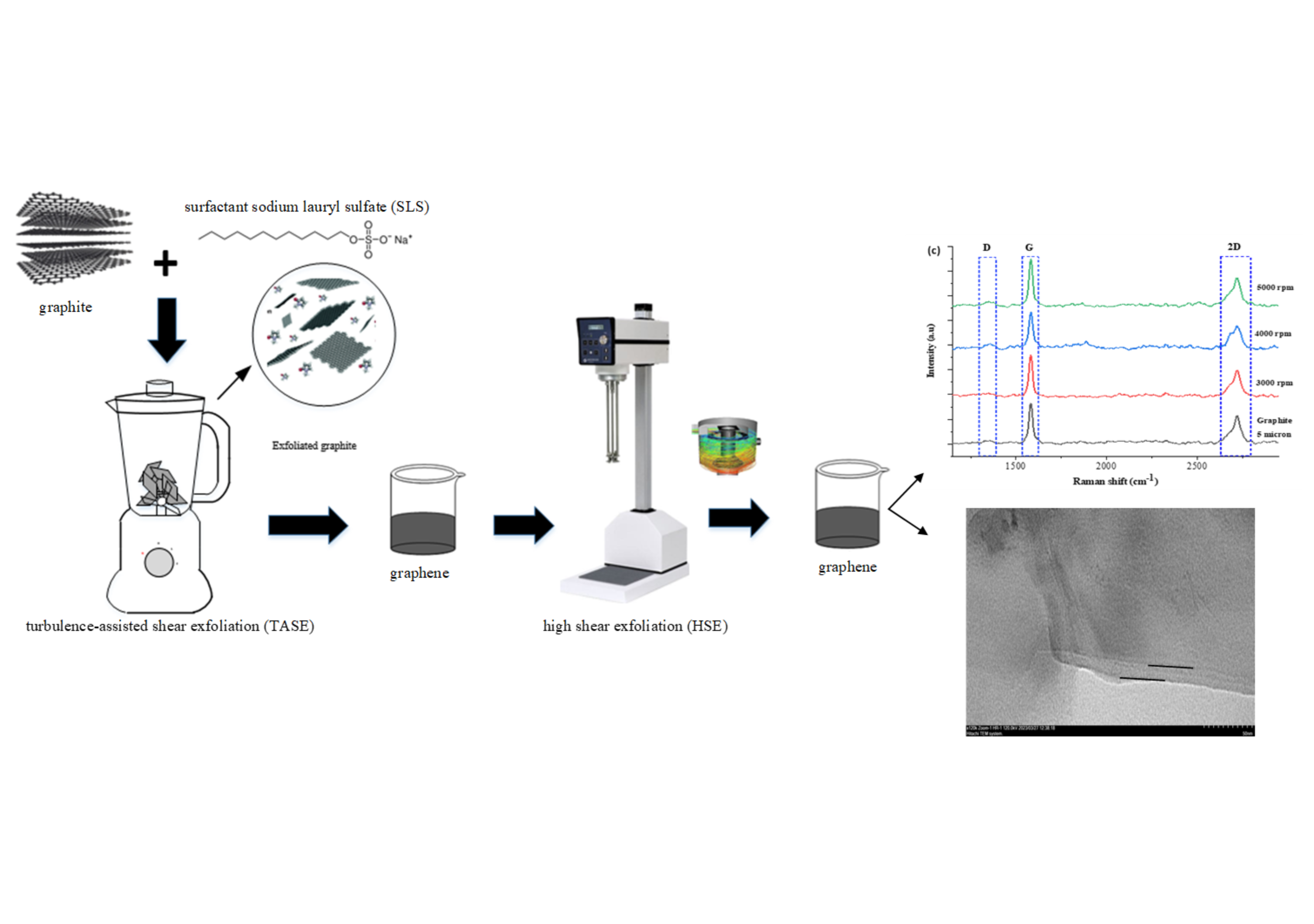

This study presents an environmentally friendly and scalable method for synthesizing high-quality few-layer graphene (FLG) through a combination of turbulence-assisted shear exfoliation (TASE) and high shear exfoliation (HSE) techniques. By systematically varying the high-shear mixer (HSM) speed (3000–5000 rpm) and processing time (1–3 hours), we precisely controlled key material attributes, including the number of graphene layers, crystallinity, lateral size, and defect density. Optimal conditions (5000 rpm, 3 hours) resulted in FLG with ~2–3 layers, confirmed by a symmetric 2D peak with a full-width at half-maximum (FWHM) of ~35 cm⁻¹ and a high I2D/IG ratio (~0.6), indicating excellent structural integrity. The ID/IG ratio (~0.1) further verified the presence of minimal defects, predominantly edge vacancies rather than oxidative disruptions. Raman imaging revealed a dominance of zigzag edge chirality, while TEM and PSA analyses demonstrated control over lateral size (~396.5 nm) and particle uniformity. The application of household dishwashing liquid as a green surfactant innovatively enabled selective and pure exfoliation. This work highlights how precise modulation of shear parameters can directly influence graphene quality, paving the way for sustainable large-scale production of low-defect FLG.

Agudosi, E. S., Abdullah, E. C., Numan, A., Mubarak, N. M., Khalid, M., & Omar, N. (2020). A review of the graphene synthesis routes and its applications in electrochemical energy storage. Critical Reviews in Solid State and Materials Sciences, 45(5), 339–377. https://doi.org/10.1080/10408436.2019.1632793

Allen, M. J., Tung, V. C., & Kaner, R. B. (2010). Honeycomb carbon: A review of graphene. Chemical Reviews, 110(1), 132–145. https://doi.org/10.1021/cr900070d

Amri, A., Hendri, Y. B., Yin, C. Y., Rahman, M. M., Altarawneh, M., & Jiang, Z. T. (2021). Very-few-layer graphene obtained from facile two-step shear exfoliation in aqueous solution. Chemical Engineering Science, 245, 1–13. https://doi.org/10.1016/j.ces.2021.116848

Atakoohi, S. E., Spennati, E., Riani, P., Carpanese, M. P., & Garbarino, G. (2024). Graphene-based materials for wastes, biomass and CO2 valorization in catalysis: A technological perspective via molten salt synthesis. Catalysis Today, 441, 114848. https://doi.org/10.1016/j.cattod.2024.114848

Bazylewski, P., & Fanchini, G. (2019). Graphene: Properties and applications. Comprehensive Nanoscience and Nanotechnology, 1–5, 287–304. https://doi.org/10.1016/B978-0-12-803581-8.10416-3

Bertran, A., Sandoval, S., Oró-Solé, J., Sánchez, À., & Tobias, G. (2020). Particle size determination from magnetization curves in reduced graphene oxide decorated with monodispersed superparamagnetic iron oxide nanoparticles. Journal of Colloid and Interface Science, 566, 107–119. https://doi.org/10.1016/j.jcis.2020.01.072

Bhaskaram, D. S., & Govindaraj, G. (2018). Carrier transport in reduced graphene oxide probed using Raman spectroscopy. The Journal of Physical Chemistry C, 122(19), 10303–10308. https://doi.org/10.1021/acs.jpcc.8b01311

Biroju, R. K., & Giri, P. K. (2014). Defect enhanced efficient physical functionalization of graphene with gold nanoparticles probed by resonance Raman spectroscopy. The Journal of Physical Chemistry C, 118(25), 13833–13843. https://doi.org/10.1021/jp500501e

Burlakov, V., & Goriely, A. (2017). Thermodynamic limit for particle monodispersity: How narrow can a particle size distribution be?. EPL, 119(5), 1–6. https://doi.org/10.1209/0295-5075/119/50001

Chen, K., & Xue, D. (2014). Preparation of colloidal graphene in quantity by electrochemical exfoliation. Journal of Colloid and Interface Science, 436, 41–46. https://doi.org/10.1016/j.jcis.2014.08.057

Choudhary, N., Hwang, S., & Choi, W. (2014). Handbook of Nanomaterials Properties (B. Bhushan, D. Luo, S. R. Schricker, W. Sigmund, & S. Zauscher, Eds.). Berlin, Heidelberg: Springer Berlin Heidelberg. https://doi.org/10.1007/978-3-642-31107-9

Denison, J. C. Jr. (2016). Spectroscopic Investigation of Thermal Conductivity in Few-layer Graphene. Clemson University, South Carolina.

Dimov, D., Amit, I., Gorrie, O., Barnes, M. D., Townsend, N. J., Neves, A. I. S., … Craciun, M. F. (2018). Ultrahigh performance nanoengineered graphene–concrete composites for multifunctional applications. Advanced Functional Materials, 28(23), 1–12. https://doi.org/10.1002/adfm.201705183

Ferralis, N. (2010). Probing mechanical properties of graphene with Raman spectroscopy. Journal of Materials Science, 45(19), 5135–5149. https://doi.org/10.1007/s10853-010-4673-3

Gai, Y., Wang, W., Xiao, D., Tan, H., Lin, M., & Zhao, Y. (2018). Exfoliation of graphite into graphene by a rotor–stator in supercritical CO2: Experiment and simulation. Industrial & Engineering Chemistry Research, 57(24), 8220–8229. https://doi.org/10.1021/acs.iecr.8b01726

Ganesan, K., Ghosh, S., Gopala Krishna, N., Ilango, S., Kamruddin, M., & Tyagi, A. K. (2016). A comparative study on defect estimation using XPS and Raman spectroscopy in few layer nanographitic structures. Physical Chemistry Chemical Physics, 18(32), 22160–22167. https://doi.org/10.1039/c6cp02033j

Godoy, A. P., Ecorchard, P., Beneš, H., Tolasz, J., Smržová, D., Seixas, L., … Donato, R. K. (2019). Ultrasound exfoliation of graphite in biphasic liquid systems containing ionic liquids: A study on the conditions for obtaining large few-layers graphene. Ultrasonics Sonochemistry, 55, 279–288. https://doi.org/10.1016/j.ultsonch.2019.01.016

Guo, J., Guo, X., Wang, S., & Yin, Y. (2016). Effects of ultrasonic treatment during acid hydrolysis on the yield, particle size and structure of cellulose nanocrystals. Carbohydrate Polymers, 135, 248–255. https://doi.org/10.1016/j.carbpol.2015.08.068

Gürünlü, B., Taşdelen-Yücedağ, Ç., & Bayramoğlu, M. (2020). Graphene synthesis by ultrasound energy-assisted exfoliation of graphite in various solvents. Crystals, 10(11), 1–12. https://doi.org/10.3390/cryst10111037

Hayyan, M., Abo-Hamad, A., AlSaadi, M. A., & Hashim, M. A. (2015). Functionalization of graphene using deep eutectic solvents. Nanoscale Research Letters, 10(1), 324. https://doi.org/10.1186/s11671-015-1004-2

Heltina, D., Mastura, D. I., Amri, A., Sembiring, M. P., & Komalasari. (2023). Comparison of synthesis methods on TiO2-graphene composites for photodegradation of compound waste. Materials Today: Proceedings, 87, 293–298. https://doi.org/10.1016/j.matpr.2023.03.284

Ho, V. D., Ng, C.-T., Ozbakkaloglu, T., Goodwin, A., McGuckin, C., Karunagaran, R. U., & Losic, D. (2020). Influence of pristine graphene particle sizes on physicochemical, microstructural and mechanical properties of Portland cement mortars. Construction and Building Materials, 264, 120188. https://doi.org/10.1016/j.conbuildmat.2020.120188

Hou, D., Liu, Q., Wang, X., Quan, Y., Qiao, Z., Yu, L., & Ding, S. (2018). Facile synthesis of graphene via reduction of graphene oxide by artemisinin in ethanol. Journal of Materiomics, 4(3), 256–265. https://doi.org/10.1016/j.jmat.2018.01.002

Jibrael, R. I., & Mohammed, M. K. A. (2016). Production of graphene powder by electrochemical exfoliation of graphite electrodes immersed in aqueous solution. Optik, 127(16), 6384–6389. https://doi.org/10.1016/j.ijleo.2016.04.101

Jorio, A., Lucchese, M. M., Stavale, F., Ferreira, E. H. M., Moutinho, M. V. O., Capaz, R. B., & Achete, C. A. (2010). Raman study of ion-induced defects in N -layer graphene. Journal of Physics Condensed Matter, 22(33). https://doi.org/10.1088/0953-8984/22/33/334204

Kaur, A., Morton, J. A., Tyurnina, A. V., Priyadarshi, A., Holland, A., Mi, J., … Tzanakis, I. (2022). Temperature as a key parameter for graphene sono-exfoliation in water. Ultrasonics Sonochemistry, 1–9. https://doi.org/10.1016/j.ultsonch.2022.106187

Kumar, S., Bhorolua, D., K. Ojha, A., & Kumar, A. (2019). Onion juice assisted green reduction of graphene oxide with tunable structural and optical properties: Effect of onion juice concentration and reaction temperature. Advanced Materials Letters, 10(1), 58–66. https://doi.org/10.5185/amlett.2019.2124

Leong, S. S., Ng, W. M., Lim, J., & Yeap, S. P. (2018). Dynamic Light Scattering: Effective Sizing Technique for Characterization of Magnetic Nanoparticles. In Handbook of Materials Characterization (pp. 77–111). Cham: Springer International Publishing. https://doi.org/10.1007/978-3-319-92955-2_3

Li, Z., Young, R. J., Backes, C., Zhao, W., Zhang, X., Zhukov, A. A., … Coleman, J. N. (2020). Mechanisms of liquid-phase exfoliation for the production of graphene. ACS Nano, 14(9), 10976–10985. https://doi.org/10.1021/acsnano.0c03916

Liang, B., Liu, K., Liu, P., Qian, L., Zhao, G., Pan, W., & Chen, C. (2021). Organic salt-assisted liquid-phase shear exfoliation of expanded graphite into graphene nanosheets. Journal of Materiomics, 7(6), 1181–1189. https://doi.org/10.1016/j.jmat.2021.03.007

Liu, J., Poh, C. K., Zhan, D., Lai, L., Lim, S. H., Wang, L., … Lin, J. (2013). Improved synthesis of graphene flakes from the multiple electrochemical exfoliation of graphite rod. Nano Energy, 2(3), 377–386. https://doi.org/10.1016/j.nanoen.2012.11.003

Luong, D. X., Bets, K. V., Algozeeb, W. A., Stanford, M. G., Kittrell, C., Chen, W., … Tour, J. M. (2020). Gram-scale bottom-up flash graphene synthesis. Nature, 577(7792), 647–651. https://doi.org/10.1038/s41586-020-1938-0

Ma, H., & Shen, Z. (2020). Exfoliation of graphene nanosheets in aqueous media. Ceramics International, 46(14), 21873–21887. https://doi.org/10.1016/j.ceramint.2020.05.314

Malard, L. M., Pimenta, M. A., Dresselhaus, G., & Dresselhaus, M. S. (2009). Raman spectroscopy in graphene. Physics Reports, 473(5–6), 51–87. https://doi.org/10.1016/j.physrep.2009.02.003

Matsumoto, M., Saito, Y., Park, C., Fukushima, T., & Aida, T. (2015). Ultrahigh-throughput exfoliation of graphite into pristine “single-layer” graphene using microwaves and molecularly engineered ionic liquids. Nature Chemistry, 7(9), 730–736. https://doi.org/10.1038/nchem.2315

Moon, I. K., Lee, J., Ruoff, R. S., & Lee, H. (2010). Reduced graphene oxide by chemical graphitization. Nature Communications, 1(1), 73. https://doi.org/10.1038/ncomms1067

Murdiya, F., Bertilsya Hendri, Y., Hamzah, A., Frimayanti, N., & Amri, A. (2022). Few-layer wrinkled graphene (FLwG) obtained from coconut-shell-based charcoal using a high-voltage plasma method. International Journal of Technology, 13(1), 157. https://doi.org/10.14716/ijtech.v13i1.4572

Paton, K. R., Varrla, E., Backes, C., Smith, R. J., Khan, U., O’Neill, A., … Coleman, J. N. (2014). Scalable production of large quantities of defect-free few-layer graphene by shear exfoliation in liquids. Nature Materials, 13(6), 624–630. https://doi.org/10.1038/nmat3944

Phiri, J., Gane, P., & Maloney, T. C. (2017). High-concentration shear-exfoliated colloidal dispersion of surfactant–polymer-stabilized few-layer graphene sheets. Journal of Materials Science, 52(13), 8321–8337. https://doi.org/10.1007/s10853-017-1049-y

Qiao, Y., Li, X., Hirtz, T., Deng, G., Wei, Y., Li, M., … Ren, T.-L. (2019). Graphene-based wearable sensors. Nanoscale, 11(41), 18923–18945. https://doi.org/10.1039/C9NR05532K

Rao, C. N. R., Biswas, K., Subrahmanyam, K. S., & Govindaraj, A. (2009). Graphene, the new nanocarbon. Journal of Materials Chemistry, 19(17), 2457. https://doi.org/10.1039/b815239j

Regasa, M. B., & Nyokong, T. (2024). Advantages of Electrochemical Exfoliation Method Over Conventional Methods. In Handbook of Electrochemical Exfoliation of Graphene and Its Derivatives (pp. 33–59). Springer. https://doi.org/10.1007/978-981-97-2128-3_2

Sato, K., Park, J. S., Saito, R., Cong, C., Yu, T., Lui, C. H., … Dresselhaus, M. S. (2011). Raman spectra of out-of-plane phonons in bilayer graphene. Physical Review B, 84(3), 035419. https://doi.org/10.1103/PhysRevB.84.035419

Shahnaz, T., Hayder, G., Shah, M. A., Ramli, M. Z., Ismail, N., Hua, C. K., … Aziz, H. A. (2024). Graphene-based nanoarchitecture as a potent cushioning/filler in polymer composites and their applications. Journal of Materials Research and Technology, 28, 2671–2698. https://doi.org/10.1016/j.jmrt.2023.12.108

Shen, J., Li, T., Long, Y., Shi, M., Li, N., & Ye, M. (2012). One-step solid state preparation of reduced graphene oxide. Carbon, 50(6), 2134–2140. https://doi.org/10.1016/j.carbon.2012.01.019

Shokrieh, M. M., Ghoreishi, S. M., Esmkhani, M., & Zhao, Z. (2014). Effects of graphene nanoplatelets and graphene nanosheets on fracture toughness of epoxy nanocomposites. Fatigue and Fracture of Engineering Materials and Structures, 37(10), 1116–1123. https://doi.org/10.1111/ffe.12191

Stafford, J., Patapas, A., Uzo, N., Matar, O. K., & Petit, C. (2018). Towards scale‐up of graphene production via nonoxidizing liquid exfoliation methods. AIChE Journal, 64(9), 3246–3276. https://doi.org/10.1002/aic.16174

Tong, X., Wang, H., Wang, G., Wan, L., Ren, Z., Bai, J., & Bai, J. (2011). Controllable synthesis of graphene sheets with different numbers of layers and effect of the number of graphene layers on the specific capacity of anode material in lithium-ion batteries. Journal of Solid State Chemistry, 184(5), 982–989. https://doi.org/10.1016/j.jssc.2011.03.004

Turner, P., Hodnett, M., Dorey, R., & Carey, J. D. (2019). Controlled sonication as a route to in-situ graphene flake size control. Scientific Reports, 9(1), 1–8. https://doi.org/10.1038/s41598-019-45059-5

Tyurnina, A. V., Tzanakis, I., Morton, J., Mi, J., Porfyrakis, K., Maciejewska, B., … Eskin, D. G. (2020). Ultrasonic exfoliation of graphene in water: A key parameter study. Carbon, 168, 737–747. https://doi.org/10.1016/j.carbon.2020.06.029

Varrla, E., Paton, K. R., Backes, C., Harvey, A., Smith, R. J., McCauley, J., & Coleman, J. N. (2014). Turbulence-assisted shear exfoliation of graphene using household detergent and a kitchen blender. Nanoscale, 6(20), 11810–11819. https://doi.org/10.1039/c4nr03560g

Vyshkvorkina, I. M., Stebunov, Y. V., Arsenin, A. V., Volkov, V. S., & Novikov, S. M. (2021). Comparison of CVD-grown and exfoliated graphene for biosensing applications. AIP Conference Proceedings, 2359, 020035. https://doi.org/10.1063/5.0054960

Wall, M. (2011). The Raman spectroscopy of graphene and the determination of layer thickness. Retrieved from https://www.researchgate.net/publication/368594583

Wang, W., Gai, Y., Song, N., Xiao, D., Tan, H., & Zhao, Y. (2018). Highly efficient production of graphene by an ultrasound coupled with a shear mixer in supercritical CO2. Industrial and Engineering Chemistry Research, 57(49), 16701–16708. https://doi.org/10.1021/acs.iecr.8b04113

Wang, Y., He, Y., Zhan, J., & Li, Z. (2022). Identification of soil particle size distribution in different sedimentary environments at river basin scale by fractal dimension. Scientific Reports, 12(1). https://doi.org/10.1038/s41598-022-15141-6

Yi, M., & Shen, Z. (2014). Kitchen blender for producing high-quality few-layer graphene. Carbon, 78, 622–626. https://doi.org/10.1016/j.carbon.2014.07.035

Yi, M., & Shen, Z. (2015). A review on mechanical exfoliation for the scalable production of graphene. Journal of Materials Chemistry A, 3(22), 11700–11715. https://doi.org/10.1039/c5ta00252d

Yi, M., & Shen, Z. (2016). Fluid dynamics: an emerging route for the scalable production of graphene in the last five years. RSC Advances, 6(76), 72525–72536. https://doi.org/10.1039/C6RA15269D

You, Y., Ni, Z., Yu, T., & Shen, Z. (2008). Edge chirality determination of graphene by Raman spectroscopy. Applied Physics Letters, 93(16), 1–3. https://doi.org/10.1063/1.3005599

Zhang, C., Tan, J., Pan, Y., Cai, X., Zou, X., Cheng, H.-M., & Liu, B. (2020). Mass production of 2D materials by intermediate-assisted grinding exfoliation. National Science Review, 7(2), 324–332. https://doi.org/10.1093/nsr/nwz156

Zhang, K., Tang, J., Yuan, J., Li, J., Sun, Y., Matsuba, Y., … Qin, L.-C. (2018). Production of few-layer graphene via enhanced high-pressure shear exfoliation in liquid for supercapacitor applications. ACS Applied Nano Materials, 1(6), 2877–2884. https://doi.org/10.1021/acsanm.8b00515

Zhang, Z., Jin, H., Wu, C., & Ji, J. (2018). Efficient production of high-quality few-layer graphene using a simple hydrodynamic-assisted exfoliation method. Nanoscale Research Letters, 13, 1–8. https://doi.org/10.1186/s11671-018-2830-9

Zhen, Z., & Zhu, H. (2018). Structure and Properties of Graphene. In Graphene (pp. 1–12). Elsevier. https://doi.org/10.1016/B978-0-12-812651-6.00001-X

Copyright (c) 2025 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.