Experimental Research on Sustained Concrete with the Partially Substitutions of GGBS, Fly ash and Silica Fume as a Cementitious Material

Downloads

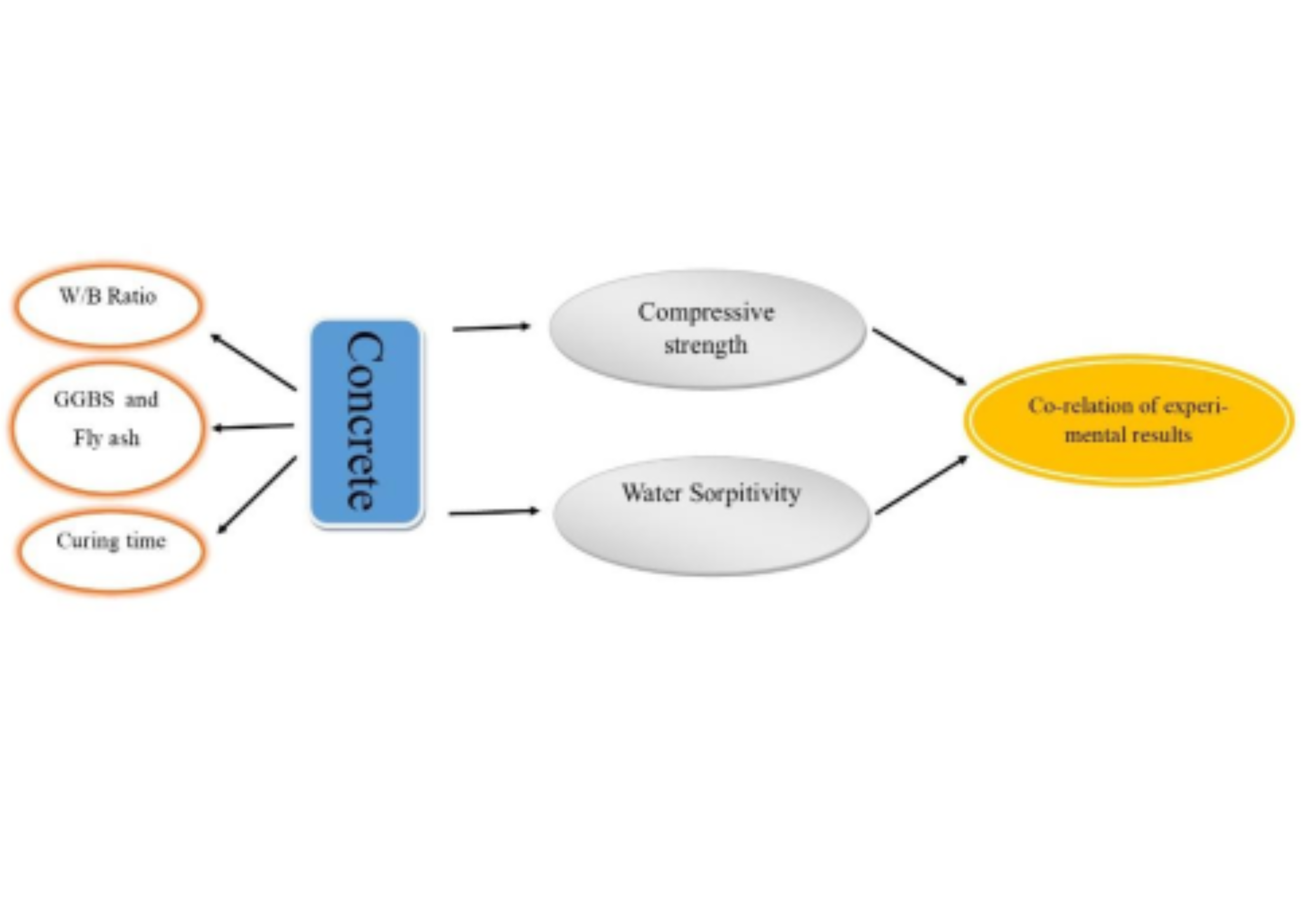

The aim of this study is to figure whether adding more cementitious elements like fly ash, ground granulated blast furnace slag (GGBS), and silica fume impacts the strength and durability of concrete. Concrete samples were put together with water-to-binder (w/b) ratios of 0.3, 0.4, and 0.5 after 28, 56, and 90 days of curing. After that, these ratios were tested before being employed. After 90 days, when 60% of the cement was replaced with fly ash at a water-to-binder (w/b) ratio of 0.3, the compressive strength reached 55.56 MPa. This is in contrast to the compressive strength of 32.89 MPa at 28 days. A 20% GGBS replacement also made the strength go up from 47.11 MPa after 28 days to 60.44 MPa after 90 days at the end of the trial. Adding 4% silica fume to each batch always made the strength grow stronger. The water sorptivity tests that were conducted to determine the durability performance showed that there was a substantial increase. The mixture with 20% GGBS and 4% silica fume, which had a water-to-binder (w/b) ratio of 0.4, had the lowest sorptivity value, which was 0.015 mm/min⁰·⁵. The study shows that alternative materials lower water permeability, structural integrity, and carbon emissions, promoting sustainable development. However, it knows that the building industry must source carefully and organize logistically to protect the environment.

Abdulnoor, A.J.G., Fayyaz, U.R., Waqas, A., Abdullah, M.Z., & Hassan, M.M. (2023). Experimental investigation of industrial wastes in concrete: Mechanical and microstructure evaluation of pumice powder and fly ash in concrete. Case Studies in Construction Materials, 18, e01999. https://doi.org/10.1016/j.cscm.2023.e01999.

Adam, N., & Aïtcin, P.C. (1998). High performance concrete—An overview. Materials and Structures, 31(2), 111–117. https://doi.org/10.1007/bf02486473

Ahmed, A., Ameer, S., Abbas, S., Abbas, W., Razzaq, A., Mohamed, A.M., & Mohamed, A. (2022). Effectiveness of ternary blend incorporating rice husk ash, silica fume and cement in preparing ASR resilient concrete. Materials, 15(6), 2125. https://doi.org/10.3390/ma15062125

Ahmed, H.U., Mohammed, A.A., & Mohammed, A. (2022). Soft computing models to predict the compressive strength of GGBS/FA-geopolymer concrete. PLOS ONE, 17(5), e0265846. https://doi.org/10.1371/journal.pone.0265846

Aktham, H.A., Johari, M.A.M., Noaman, A.T., Bunnori, N.M., & Majid, T.A. (2022). Effect of the incorporation of PET fiber and ternary blended binder on the flexural and tensile behaviour of ultra-high performance green concrete. Construction and Building Materials, 331, 127306. https://doi.org/10.1016/j.conbuildmat.2022.127306

Akhtar, M.N., Jameel, M., Ibrahim, Z., & Bunnori, N.M. (2022). Incorporation of recycled aggregates and silica fume in concrete: an environmental savior—A systematic review. Journal of Materials Research and Technology, 20, 4525-4544. https://doi.org/10.1016/j.jmrt.2022.09.021.

Alateah, A.H., Khaled Al Sodani, A.A., Yusuf, M.O., Adewumi, A.A., Al Tholaia, M.M.H., Bakare, A.O., Ibrahim, M., & Usman, A.K. (2023). Modelling of strength characteristics of silica fume/glass ternary blended concrete using destructive and non- destructive testing methods. Journal of Materials Research and Technology, 22, 997–1013. https://doi.org/10.1016/j.jmrt.2022.11.180

Ardalan, B.R., Joshaghani, A., & Hooton, D. (2017). Workability retention and compressive strength of self-compacting concrete incorporating pumice powder and silica fume. Construction and Building Materials, 134, 116–122. https://doi.org/10.1016/j.conbuildmat.2016.12.090

Arıoğlu, N., Girgin, Z.C., & Arıoğlu, E. (2006). Evaluation of ratio between splitting tensile strength and compressive strength for concretes upto 120MPa and its application in strength criterion. ACI Materials Journal, 103(1). https://doi.org/10.14359/15123

Asadollahfardi, G., Katabi, A., Pravin, T., & Panahandeh, A. (2019). Environmental life cycle assessment of concrete with different mixed designs. International Journal of Construction Management, 21(7), 665–676. https://doi.org/10.1080/15623599.2019.1579015

Babu Padavala, S.S.A., Subhashish, D., Veerendra, G.T.N., & Phani Manoj, A.V. (2023). Performance evaluation of ternary blended cement concrete partially replacement of natural sand with granite quarry dust. Hybrid Advances, 4, 100082. https://doi.org/10.1016/j.hybadv.2023.100082

Babu, G.K., Venkateswara Rao, K., Subhashish, D., & Veerendra, G.T.N. (2023). Performance studies on quaternary blended geo polymer concrete. Hybrid Advances, 2, 100019. https://doi.org/10.1016/j.hybadv.2023.100019

Brzozowski, P., Strzałkowski, J., Rychtowski, P., Wróbel, R., Tryba, B., & Horszczaruk, E. (2021). Effect of nano-SiO2 on the microstructure and mechanical properties of concrete under high temperature conditions. Materials, 15(1), 166. https://doi.org/10.3390/ma15010166

Camoes, A., Branco, F.G., Aguiar, J.B., & Fanguerio, R. (2019). Recycling of biomass and coal fly ash as cement replacement material and its effect on hydration and carbonation of concrete. Waste Management, 94, 39–48. https://doi.org/10.1016/j.wasman.2019.05.044

Cheah, C.B., Kang, C.W., & Wei, O.C. (2020). The influence of type and combination of poly carboxylate ether super plasticizer on the mechanical properties and microstructure of slag-silica fume ternary blended self-consolidating concrete. Journal of Building Engineering, 31, 101412. https://doi.org/10.1016/j.jobe.2020.101412

Chen, J.J., Ng, P.L., Chu, S.H., Guan, G.X., & Kwan, A.K.H. (2020). Ternary blending with metakaolin and silica fume to improve packing density and performance of binder paste. Construction and Building Materials, 252, 119031. https://doi.org/10.1016/j.conbuildmat.2020.119031

Choi, J.H., Kim, D., Sam Ko, M., Lee, D.E., Wi, K., & Lee, H.S. (2023). Compressive strength prediction of ternary-blended concrete using deep neural network with tuned hyper parameters. Journal of Building Engineering, 75, 107004.https://doi.org/10.1016/j.jobe.2023.107004

Chu, S.H., Chen, J.J., Li, L.G., Ng, P.L., & Kwan, A.K.H. (2021). Roles of packing density and slurry film thickness in synergistic effects of metakaolin and silica fume. Powder Technology, 387, 575–583. https://doi.org/10.1016/j.powtec.2021.04.029

Dalin, G., Alzoubi, A.E., Alzboon, A., & Hanandeh, S. (2022). Prediction of concrete compressive strength with GGBFS and fly ash using multilayer perceptron algorithm, random forest regression and K-nearest neighbor regression. Asian Journal of Civil Engineering, 24(1), 169–177. https://doi.org/10.1007/s42107-022-00495-z

Deprizon, S., Li, W., Hisyam, M.N., Memom, Z.A., & Sultan, B. (2023). Research on performance monitoring of binary nano modified concrete based on temperature variation. Case Studies in Construction Materials, 19, e02373–e02373. https://doi.org/10.1016/j.cscm.2023.e02373

Duan, Z., Deng, Q., Liang, C., Ma, Z., & Wu, H. (2023). Up cycling of recycled plastic fiber for sustainable cementitious composites: A critical review and new perspective. Cement and Concrete Composites, 142, 105192–105192. https://doi.org/10.1016/j.cemconcomp.2023.105192

Erdem, T.K., & Önder, K. (2008). Use of binary and ternary blends in high strength concrete. Construction and Building Materials, 22(7), 1477–1483. https://doi.org/10.1016/j.conbuildmat.2007.03.026

Frías, M., Ramirez, S.M., Vigil de la, R.V., & Carrasco, L.J.F. (2021). Reactivity in cement pastes bearing fine fraction concrete and glass from construction and demolition waste: Microstructural analysis of viability. Cement and Concrete Research, 148, 106531. https://doi.org/10.1016/j.cemconres.2021.106531

Gutierrez, K.P.B., Agustin, L.H.M., Jesus, M.S.L., Moreno, A.H., & Castro, S.A.Z. (2019). Recent progress in nano materials for modern concrete infrastructure: Advantages and challenges. Materials, 12(21), 3548. https://doi.org/10.3390/ma12213548

Hakeem, I. Y., Alharthai, M., Amin, M., Zeyad, A.M., Tayeh, B.A., & Agwa, I.S. (2023). Properties of sustainable high-strength concrete containing large quantities of industrial wastes, nanosilica and recycled aggregates. Journal of Materials Research and Technology, 24, 7444–7461. https://doi.org/10.1016/j.jmrt.2023.05.050

Halit, Y., Mert, Y.Y., Yigiter, H., Aydin, S., & Turkel, S. (2010). Mechanical properties of reactive powder concrete containing high volumes of ground granulated blast furnace slag. Cement and Concrete Composites, 32(8), 639–648. https://doi.org/10.1016/j.cemconcomp.2010.07.005.

Hasan, Z.A., Mohammed, S.N., & Mohammed, K.A. (2021). Properties of reactive powder concrete containing different combinations of fly ash and metakaolin. Materials today: Proceedings, 42, 2436–2440. https://doi.org/10.1016/j.matpr.2020.12.556

Hashmi, A.F., Shariq, M., & Baqi, A. (2021). An investigation into age-dependent strength, elastic modulus and deflection of low calcium fly ash concrete for sustainable construction. Construction and Building Materials, 282, 122772. https://doi.org/10.1016/j.conbuildmat.2021.122772.

Hessam, A., Mohammad, J.T.A., Ashrafian, A., & Rasekh, H. (2019). Ternary blended cement: An eco-friendly alternative to improve resistivity of high-performance self- consolidating concrete against elevated temperature. Journal of Cleaner Production, 223, 575–586. https://doi.org/10.1016/j.jclepro.2019.03.054

Hosseinzadeh, M., Dehestani, M., & Hosseinzadeh, A. (2023). Prediction of mechanical properties of recycled aggregate fly ash concrete employing machine learning algorithms. Journal of Building Engineering, 74, 107006. https://doi.org/10.1016/j.jobe.2023.107006

Huon, V., Wattrisse, B., Youssoufi, M.S.E., & Andre, C. (2007). Mechanical behavior of terra cotta ceramics characterized by kinematic full- field measurements. Journal of Materials in Civil Engineering, 19(8), 642–647. https://doi.org/10.1061/(ASCE)0899-1561(2007)19:8(642)

Hussein, H., Alattar, A., Tayeh, B., Yahaya, F., & Thomas, B. (2022). Effect of recycled waste glass on the properties of high-performance concrete: A critical review. Case Studies in Construction Materials, 17, e01149. https://doi.org/10.1016/j.cscm.2022.e01149

Jumaa, N.H., Ali, I.M., Mohammed, S.N., & Falah, M.W. (2022). Strength and microstructural properties of binary and ternary blends in fly ash-based geopolymer concrete. Case Studies in Construction Materials, 17, e01317. https://doi.org/10.1016/j.cscm.2022.e01317.

Kang, C.W., Cheah, C.B., Wei, O.C., & Ken, P.W. (2020). The properties of slag- silica fume ternary blended mortar with quarry dust. Journal of Mechanical Engineering and Sciences, 14(1), 6443–6451. https://doi.org/10.15282/jmes.14.1.2020.19.0504

Karthik, D., Nirmalkumar, K., & Priyadharshini, R. (2021). Characteristic assessment of self-compacting concrete with supplementary cementitious materials. Construction and Building Materials, 297, 123845. https://doi.org/10.1016/j.conbuildmat.2021.123845.

Kumutha, R., Vijai, K., & Vinu, S.K. (2021). Compressive strength of ternary blended geopolymer concrete composites. Electronic Journal of Structural Engineering, 21, 10–18. https://doi.org/10.56748/ejse.21287.

Kwabena, B., & Khorami, M. (2023). Hydration, Reactivity and durability performance of low-grade calcined clay- silica fume hybrid mortar. Applied Sciences, 13(21), 11906–1906. https://doi.org/10.3390/app132111906

Li, W., Hisyam, M.N., & Memom, Z.A. (2022). Effect of ternary blends on microstructure and mechanical strength of concrete. Journal of Materials Research and Technology, 20, 2345–2354

Lianfei, N., Xiangdong, L., Jing, L., Zhu, B., & Qi, L. (2022). Analysis of high performance concrete mixed with nano-silica in front of sulfate attack. Materials, 15(21), 7614–7614. https://doi.org/10.3390/ma15217614

Mehrab, N., & Taghvaee, V.M. (2021). Sustainable concrete for circular economy: A review on use of waste glass. Glass Structures & Engineering, 7, 3-22. https://doi.org/10.1007/s40940-021-00155-9

Mehta, A., & Deepankar Kumar, A. (2019). Silica fume and waste glass in cement concrete production: A review. Journal of Building Engineering, 29, 100888. https://doi.org/10.1016/j.jobe.2019.100888

Mehta, P.K., & Gjørv, O.E. (1982). Properties of portland cement concrete containing fly ash and condensed silica-fume. Cement and Concrete Research, 12(5), 587–595. https://doi.org/10.1016/0008-8846(82)90019-9

Milena, S.M., Zavadskas, E.K., Bjork, F., & Turskis, A., (2014). Multi-criteria decision-making system for sustainable building assessment/certification. Archives of Civil and Mechanical Engineering, 15(1), 11-18. https://doi.org/10.1016/j.acme.2014.09.001

Mohamed, A., AL-Tam, S.M., Elemam, W.E., Alanazi, H., Elgendy, G.M., & Tahwia, A.M. (2023). Development of ultra- high-performance concrete with low environmental impact integrated with metakaolin and industrial wastes. Case Studies in Construction Materials, 18, e01724–e01724). https://doi.org/10.1016/j.cscm.2022.e01724.

Mohammed, N.S., Ali, I.M., Hussein, A.M., Shubbar, A.A., Kareem, Q.T., & AbdilAmeer, A.T. (2020). Utilization of locally produced waste in the production of sustainable mortar. Case Studies in Construction Materials, 13, e00464. https://doi.org/10.1016/j.cscm.2020.e00464

Nafisa, T., & Rabin, T. (2020). Sustainable use of recycled glass powder as cement replacement in concrete. The Open Waste Management Journal, 13(1), 1–13. https://doi.org/10.2174/1874347102013010001

Nagaraju, T.V., Sireesha, M., Azab, M., Alisha, S.S., El Hachem, C., Adamu, M., & S Murthy, P. S. R.(2023). Prediction of high strength ternary blended concrete containing different silica proportions using machine learning approaches. Results in Engineering, 17, 100973–100973. https://doi.org/10.1016/j.rineng.2023.100973.

Okashah, A.M., Abdulkareem, M., Ali, A.Z.M., Ayeronfe, F., & Majid, M.Z.A. (2020). Application of automobile used engine oils and silica fume to improve concrete properties for eco-friendly construction. Sustainability in Construction Materials and Technologies, 24(1), 123–142. https://doi.org/10.2478/rtuect-2020-0008

Piro, N.S., Mohammed, A.S., & Samir, M.H. (2022). RETRACTED: The impact of GGBS and ferrous on the flow of electrical current and compressive strength of concrete. Construction and Building Materials, 349, 128639. https://doi.org/10.1016/j.conbuildmat.2022.128639

Prakash, S., Kumar, S., Biswas, R., & Rai, B. (2021). Influence of silica fume and ground granulated blast furnace slag on the engineering properties of ultra-high-performance concrete. Innovative Infrastructure Solutions, 7(1). https://doi.org/10.1007/s41062-021-00714-7.

Qureshi, L.A., Ali, B., & Ali, A. (2020). Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete. Construction and Building Materials, 263, 120636. https://doi.org/10.1016/j.conbuildmat.2020.120636.

Raghavender, C., Durga Prasad, R., Sri Rama Chand, N., & Janardhan Yadav, M. (2021). Performance evaluation of self-compacting concrete containing fly ash, silica fume and nano titanium oxide. Materials today: Proceedings, 43, 2348–2354. https://doi.org/10.1016/j.matpr.2021.01.681.

Rajesh, K., Anilkumar, N., & VijayaGiri, J. (2013). Experimental investigation on self compacting concrete using quarry dust. Int J S Res Sci. Tech., 4(5), 799-806 https://ijsrst.com/paper/2793.pdf

Rohith Kumar, V., & Reddy Suda, V.B. (2021). Experimental investigation on ternary concrete containing of granulated blast furnace slag as a partial replacement to fine aggregate. IOP Conference Series, 1185(1), 012016–012016. https://doi.org/10.1088/1757-899x/1185/1/012016.

Rongjin, C., Tong, W., & Fu, C.Q. (2022). Thermal degradation of potassium-activated ternary slag-fly ash-silica fume binders. Construction and Building Materials, 320, 126304–126304. https://doi.org/10.1016/j.conbuildmat.2021.126304

Sai, K. P. P., Rao, B. K., Veerendra, G.T, & Subhashish, D. (2023). A critical examination on service life prediction of RC structures with respect to chloride-ion penetration. Journal of Bio- and Tribo-Corrosion, 10(1), 5. https://doi.org/10.1007/s40735-023-00808-y

SathishKumar, V., Ganesan, N., & Indira, P.V. (2021). Effect of hybrid fibers on the durability characteristics of ternary blend geopolymer concrete. Journal of Composites Science, 5(10), 279. https://doi.org/10.3390/jcs5100279.

Shahmansouri, A.A., Yazdani, M., Ghanbari, S., & Bengar, H.A. (2021). Artificial neural network model to predict the compressive strength of eco-friendly geopolymer concrete incorporating silica fume and natural zeolite. Journal of Cleaner Production, 279, 123697. https://doi.org/10.1016/j.jclepro.2020.123697.

Shamsad, A., Rasul, M., Adekunle, S.K., Al Dulaijan, S.U., Maslehuddin, M., & Syed, I.A. (2019). Mechanical properties of steel fiber-reinforced UHPC mixtures exposed to elevated temperature: Effects of exposure duration and fiber content. Composites Part B: Engineering, 168, 291–301. https://doi.org/10.1016/j.compositesb.2018.12.083

Sonali, P., & Puja, R. (2023). Durability assessment of quaternary blended recycled aggregate concrete under chloride environment. Materials today: Proceedings. In Press, Corrected Proof. https://doi.org/10.1016/j.matpr.2023.03.686

Srinivas, D., Ramagiri, K.K., Arkamitra, K., & Adek, D. (2021). Experimental characterization of quaternary blended mortar exposed to marine environment using mechanical strength, corrosion resistance and chemical composition. Journal of Building Engineering, 42, 102822. https://doi.org/10.1016/j.jobe.2021.102822.

Suda, V.B.R., & SrinivasaRao, P. (2020). Experimental investigation on optimum usage of micro silica and GGBS for the strength characteristics of concrete. Materials today: Proceedings, 27, 805–811. https://doi.org/10.1016/j.matpr.2019.12.354.

Thomas, M.D.A., Shehata, M.H., Shashiprakash, S.G., Hopkins, D.S., & Cail, K. (1999). Use of ternary cementitious systems containing silica fume and fly ash in concrete. Cement and Concrete Research, 29(8), 1207– 1214. https://doi.org/10.1016/s0008-8846(99)00096-4

Veerendra, G.T.N., Kumaravel, B., Rama Rao, P.K., Subhashish, D., & Phani Manoj, A.V. (2023). Forecasting models for surface water quality using predictive analytics. Environment, Development and Sustainability, 26, 15931-15951. https://doi.org/10.1007/s10668-023-03280-3

Wang, J., Peng, D., Zhou, Z., Dongyu, X., Ning, X., & Cheng, X. (2019). Effect of nano-silica on hydration, microstructure of alkali-activated slag. Construction and Building Materials, 220, 10–118. https://doi.org/10.1016/j.conbuildmat.2019.05.158

Wilson, E., Taylor, P., Ceylan, H., & Bektas, F. (2013). Effect of water-to-binder ratio, air content, and type of cementitious materials on fresh and hardened properties of binary and ternary blended concrete. Journal of Materials in Civil Engineering, 26(6).04014002. https://doi.org/10.1061/(asce)mt.1943-5533.0000900

Yunchao, T., Chen, Z., Wanhui, F., & Yumei, N. (2021). Combined effects of nano- silica and silica fume on the mechanical behavior of recycled aggregate concrete. Nanotechnology Reviews, 10(1), 819–838, https://doi.org/10.1515/ntrev-2021-0058.

Yusuf, M.O., Khaled Al Sodani, A.A., AlAteah, A.H., Mohammed Al Tholaia, M.H., Adewumi, A.A., Bakare, A.O., Usman, A.K., & Ibrahim, M. (2022). Performances of the synergy of silica fume and waste glass powder in ternary blended concrete. Recycling Applications of Construction Materials, 12(13), 6637–6637. https://doi.org/10.3390/app12136637

Zhang, B., Tao, J., Ma, Y., & Zhang, Q. (2022). Effect of Metakaolin and magnesium oxide on flexural strength of ultra- high performance concrete. Cement and Concrete Composites, 131, 104582. https://doi.org/10.1016/j.cemconcomp.2022.104582

Zhang, A., Yang, W., Yong, G., Yuanbo, D., & Liu, P. (2021). Effects of nano-SiO2 and nano- Al2O3 on mechanical and durability properties of cement-based materials: A comparative study. Journal of Building Engineering, 34, 101936–101936. https://doi.org/10.1016/j.jobe.2020.101936

Zhang, X., Yu, R., Zhang, J.J., & Shui, Z., (2022). A low-carbon alkali activated slag based ultra-high performance concrete (UHPC) reaction kinetics and microstructure development. Journal of Cleaner Production, 363, 132416. https://doi.org/10.1016/j.jclepro.2022.132416

Zhenhai, X., Zhaoheng, G., Zhao, Y., Shujun, L., Luo, X., Chen, G., Cheng, L., & Gao, J. (2023). Hydration of blended cement with high-volume slag and nano-silica. Journal of Building Engineering, 64, 105657. https://doi.org/10.1016/j.jobe.2022.105657

Copyright (c) 2025 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.