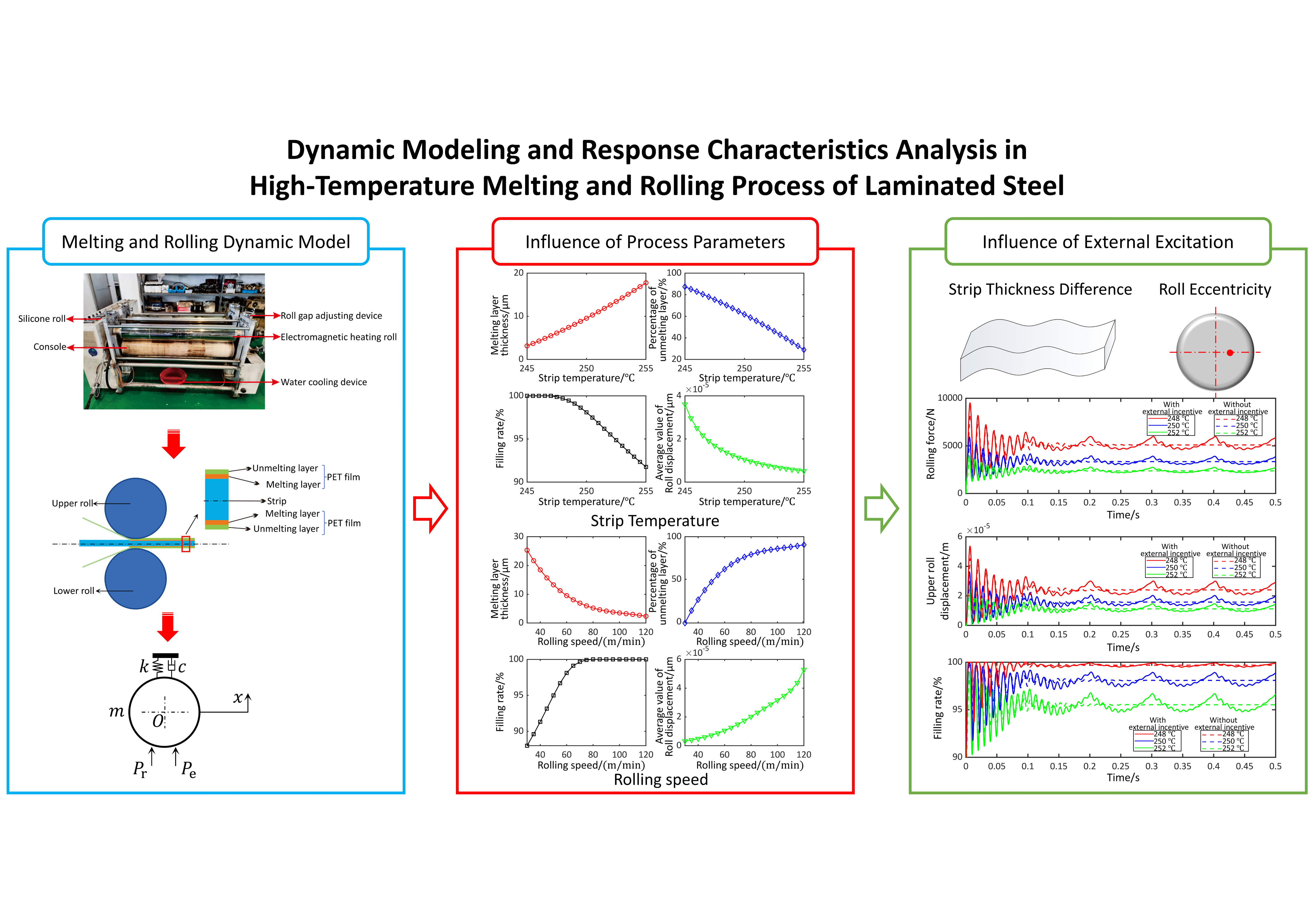

Dynamic Modeling and Response Characteristics Analysis in High-Temperature Melting and Rolling Process of Laminated Steel

Downloads

High-temperature melting and rolling is the key process of laminated steel production. The dynamic fluctuation of the rolling force during the film covering process causes an alternating effect of positive and negative pressures in the film covering area. The roll vibration causes the film to vibrate up and down, leading to the generation and intensification of bubbles, which seriously affects the product quality. In this study, considering the nonlinear stiffness characteristics of a polyethylene terephthalate (PET) film under unidirectional compression in the roll gap, a melting and rolling dynamic model with the structure and process coupled was established. Taking the melting layer and the rolling force as intermediate variables, process parameters such as strip temperature and rolling speed were introduced into the dynamic model, and the influence of process parameters on the film filling rate and the roll vibration displacement response was discussed. Considering the external disturbances of the strip thickness difference and the roll eccentricity, the dynamic characteristics of the rolling force, roll displacement, and filling rate under different strip temperatures and rolling speeds were analysed. The research results indicated that with an increase in the rolling speed and a decrease in the strip temperature, the filling rate, roll displacement, and rolling force increased, affecting the quality of laminated steel. Therefore, modeling the dynamic mechanism and studying the dynamic rolling force characteristics of the high-temperature melting and rolling process of laminated steel can provide a theoretical basis for controlling and optimizing of the film covering process.

Barbaro, G., Galdi, M., Maio, L. (2015). Effect of Bopet film surface treatments on adhesion performance of biodegradable coatings for packaging applications. European Polymer Journal, 68, 80–89.

Belodedenko, S., Hanush, V., Baglay, A. (2020). Fatigue resistance models of structural for risk based inspection. Civil Engineering Journal, 6(02), 375–383.

Belodedenko, S., Hrechanyі, O., Hanush V. (2024). Experimental and analytical ways of finding the function of the maximum accumulated damage under operating modes with overloads. Advances in Industrial and Manufacturing Engineering, 8, 100137.

Boelen, B., Denhartog, H., Vanderweijde, H. (2004). Product performance of polymer coated packaging steel study of the mechanism of defect growth in cans. Progress in Organic Coatings, 50(1), 40–46.

Chen, J., Fu, N., Wang, R. (2020). Effect of surface structure on interfacial bonding strength of metal/plastic composite injection molding. China plastics, 34(04), 49–53.

Fu, X. (2013). Research on polymer coated steel products and their can making technology. Shanghai Packaging, 4, 40–43.

Gao, Z., Bai, L., Li, Q. (2017). Research on critical rolling speed of self-excited vibration in the tandem rolling process of thin strip. Journal of Mechanical Engineering, 53(12), 118–132.

Gao, Z., Liu, Y., Zhang, Q. (2020). Chatter model with structure–process–control coupled and stability analyses in the cold rolling system. Mechanical Systems and Signal Processing, 140, 106692.

Hou, L., Shi, J., Tang, Q. (2015). Temperature field calculation for plate laminating process. Baosteel Technology, 5, 29–34.

Hrechanyі, O. (2024). Developing an algorithm for planning the periodicity of controls for a random process model. Results in Engineering, 24, 102964.

Komai, M., Taniguchi, A., Shimizu, N. (1997). Effects of composition and microstructure of hydrated chromium oxide on adhesive property of Pet/I film laminated Tfs. Tetsu-to-Hagane, 83(6), 377–382.

Li, J. (2014). Polymer coated steel container packaging material and its application technology. Hunan Packaging, 4, 29–34.

Liu, J. (2021). Study on film thickness evolution and interface bonding behavior of polymer coated steel strip. University of Science and Technology Beijing. [Doctoral dissertation].

Lu, X., Sun, J., Li, G. (2019). Dynamic analysis of vibration stability in tandem cold rolling mill. Journal of Materials Processing Technology, 272, 47–57.

Morita, S., Iwashita, H., Tanaka, A. (2000). Variations of biaxial orientation of polyester film on laminated steel in the laminating process. Tetsu-to-Hagane, 86(3), 171–175.

Palkowski, H., Lange, G. (2007). Production and forming behavior of austenitic steel sandwich composites with a polymer core layer. Materialwissenschaft und Werkstofftechnik, 38(2), 85–89.

Qiao J. (2000). Application and development of Wuxi Steel in China. China Metallurgy, 6, 12–13.

Song, W., Wang, J., Bai, J. (2015). Research on properties of polymer coated steel and coating iron in metal packaging applications. China Packing Industry, 21, 73–75.

Tanaka, A., Hanafusa, T., Kojyo, H. (2009). Adhesion of biaxially oriented polyethylene terephthalate film to tin free steel. Transactions of the Iron and Steel Institute of Japan, 27(8), 638–644.

Volodymyr, T., Hrechanyі, O. (2024). Features of the formation of the nanostructural state of the surface layer of steel parts during processing and operation. Journal of Chemical Technology and Metallurgy, 3(59), 713–720.

Yang, W. (2006). New metal packaging material coating steel and its development. Shanghai Packaging, 2, 32–33.

Zumelzu, E., Rull, F., Boettcher, A. (2006). Characterization and micro- and ultra-structural analysis of Pet-based co-rolled composite electrolytic chromium coated steel. Journal of Materials Processing Technology, 173(1), 34–39.

Zumelzu, E., Cabezas, C., Delgado, F. (2004). Performance and degradation analyses of traditional and Eccs canning tin plates in citric-citrate medium. Journal of Materials Processing Technology, 152(3), 384–388.

Zumelzu, E., Angulo, C., Cabezas, C. (2013). Characterization of nanometric chromium coatings in metal polymer composites. Surface Engineering, 29(8), 620–626.

Zhang, Q., Liu, J., Zhang, B. (2019). Advances in theory and technology for laminating of polymer-coated steel. Journal of Mechanical Engineering, 55(08), 30–45.

Zhang, B., Zhang, Q., Geng, L. (2023). Study on Interface heat transfer and polymer film melting-filling behavior during the laminating process for laminated steel. Journal of Mechanical Engineering, 59(6), 61–71.

Copyright (c) 2025 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.