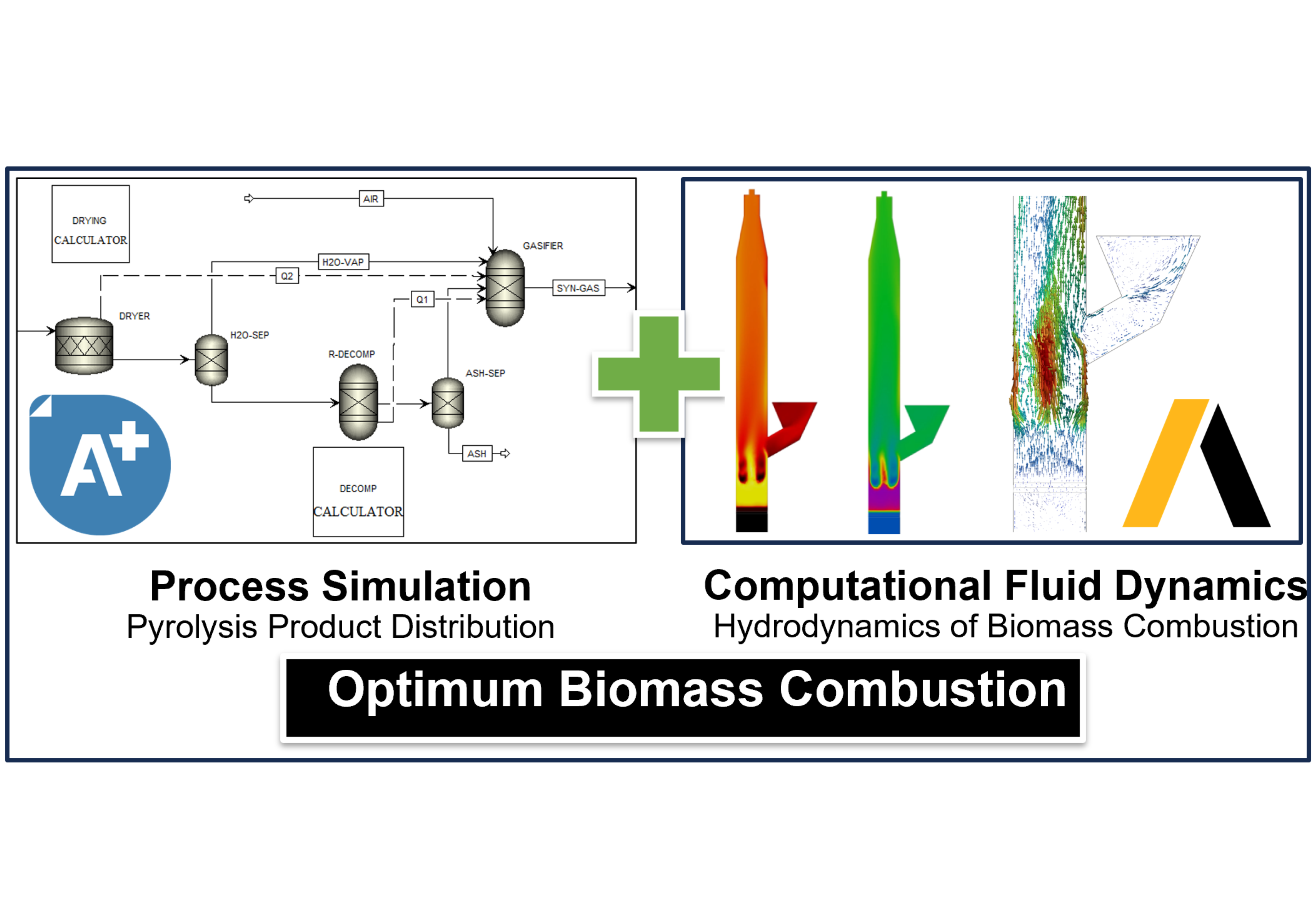

Integrated CFD and Aspen Plus Simulation for Optimizing Biomass Combustion: A Study on Sugarcane Bagasse

Downloads

This study presents an integrated simulation approach to optimize biomass combustion using sugarcane bagasse as a renewable feedstock. Computational fluid dynamics (CFD) was employed to model combustion hydrodynamics, while Aspen Plus was used to simulate pyrolysis product distribution based on Gibbs free energy minimization. The simulation involved key parameters such as air-fuel ratio, excess air level (100% and 200%), and combustion temperature profiles, which were validated against experimental data from a lab-scale grate-fired furnace. The pyrolysis results revealed that increasing the temperature from 400°C to 600°C significantly enhanced CO and H₂ concentrations, thereby improving syngas reactivity. CFD analysis showed that, at 100% excess air, CO₂ concentration reached 9.15% with an average freeboard temperature of 405.2°C, while at 200% excess air, the CO₂ dropped to 6.46% and the temperature decreased to 397.9°C, indicating reduced combustion efficiency. These results underscore the importance of optimizing air supply to enhance combustion performance and minimize unburnt volatiles. The findings confirm that integrating CFD and Aspen Plus simulations provides a reliable framework for improving the efficiency and environmental performance of biomass combustion systems.

Abhijeet, P., Swagathnath, G., Rangabhashiyam, S., Asok Rajkumar, M., & Balasubramanian, P. (2020). Prediction of pyrolytic product composition and yield for various grass biomass feedstocks. Biomass Conversion and Biorefinery, 10(3), 663–674. https://doi.org/10.1007/s13399-019-00475-5

Aghaalikhani, A., Schmid, J. C., Borello, D., Fuchs, J., Benedikt, F., Hofbauer, H., Rispoli, F., Henriksen, U. B., Sárossy, Z., & Cedola, L. (2019). Detailed modelling of biomass steam gasification in a dual fluidized bed gasifier with temperature variation. Renewable Energy, 143, 703–718. https://doi.org/10.1016/J.RENENE.2019.05.022

Ali, F., Dawood, A., Hussain, A., Alnasir, M. H., Khan, M. A., Butt, T. M., Janjua, N. K., & Hamid, A. (2024). Fueling the future: biomass applications for green and sustainable energy. Discover Sustainability, 5(1). https://doi.org/10.1007/s43621-024-00309-z

Azarya, E. A., Gilar Nugraha, M., & Saptoadi, H. (2025). Evaluation of Catalytic Converter Utilization in Biomass Combustion Flue Gas Treatment. Karya International Journal of Biofuel and Bioenergy, 1, 48–57. https://doi.org/10.37934/kijbb.1.1.4857

Batista, R. M., Converti, A., Pappalardo, J., Benachour, M., & Sarubbo, L. A. (2023). Tools for Optimization of Biomass-to-Energy Conversion Processes. Processes, 11(3), 854. https://doi.org/10.3390/pr11030854

Cahyono, R. B., Nugraha, M. G., Pratama, A. R., Insani, V. F. S., Irianto, D., Anugia, Z., Sasmita, F. A., Hadiyati, K. R., & Ariyanto, T. (2025). Biogas potential for sustainable power generation in Indonesia: opportunity and techno-economic analysis. Bioresource Technology Reports, 30, 102143. https://doi.org/10.1016/j.biteb.2025.102143

Chatterjee, R., Sajjadi, B., Chen, W. Y., Mattern, D. L., Hammer, N., Raman, V., & Dorris, A. (2020). Effect of Pyrolysis Temperature on PhysicoChemical Properties and Acoustic-Based Amination of Biochar for Efficient CO2 Adsorption. Frontiers in Energy Research, 8(May), 1–18. https://doi.org/10.3389/fenrg.2020.00085

Dernbecher, A., Dieguez-Alonso, A., Ortwein, A., & Tabet, F. (2019). Review on modelling approaches based on computational fluid dynamics for biomass combustion systems. Biomass Conversion and Biorefinery (Vol. 9, Issue 1). https://doi.org/10.1007/s13399-019-00370-z

Habibi, M. Y., Nugraha, M. G., Hidayat, M., & Saptoadi, H. (2024). Simulation of coconut shell combustion in a grate-fired furnace using distributed pyrolysis products model. AIP Conference Proceedings, 2836(1), 060001. https://doi.org/10.1063/5.0207275

Liu, Y., Yang, X., Zhang, J., & Zhu, Z. (2022). Process Simulation of Preparing Biochar by Biomass Pyrolysis Via Aspen Plus and Its Economic Evaluation. Waste and Biomass Valorization, 13(5), 2609–2622. https://doi.org/10.1007/s12649-021-01671-z

Mehdi, M., Ammar Taqvi, S. A., Shaikh, A. A., Khan, S., Naqvi, S. R., Shahbaz, M., & Juchelková, D. (2023). Aspen plus simulation model of municipal solid waste gasification of metropolitan city for syngas production. Fuel, 344. https://doi.org/10.1016/j.fuel.2023.128128

Mohapatra, S. S., Gouda, N., & Singh, R. K. (2023). Investigation on Thermokinetic Study and Optimization of Sugarcane Bagasse Thermal Pyrolysis. Sugar Tech, 25(1), 198–209. https://doi.org/10.1007/s12355-022-01171-x

Morais, L. C., Maia, A. A. D., Guandique, M. E. G., & Rosa, A. H. (2017). Pyrolysis and combustion of sugarcane bagasse. Journal of Thermal Analysis and Calorimetry, 129(3), 1813–1822. https://doi.org/10.1007/s10973-017-6329-x

Newman, S. G., Kwong, K. Y., & Marek, E. J. (2024). A Systematic Approach to Determining the Kinetics of the Combustion of Biomass Char in a Fluidised Bed Reactor. Processes, 12(10). https://doi.org/10.3390/pr12102103

Nugraha, M. G., Ariyanto, T., Pratama, A. R., Naratama, N. C., Wardhani, A. T. R., Insani, V. F. S., Irianto, D., Hendarto, W. A., Asbah, Z., &

Prianto, R. (2025). Municipal Solid Waste Potential for Indonesian Electrical Energy Sharing: Process Simulation Study. ASEAN Journal of Chemical Engineering, 25(1), 97–114. https://doi.org/10.22146/ajche.16716

Nugraha, M. G., Mozasurya, E. D., Hidayat, M., & Saptoadi, H. (2023). Evaluation of combustion characteristics in biomass residues open burning. Materials Today: Proceedings, 87, 45–50. https://doi.org/10.1016/j.matpr.2023.02.098

Nugraha, M. G., Saputra, D. D., Ilyas, K., & Hidayat, M. (2023). Numerical Investigation of Hydrodynamics in Inline Mixers. CFD Letters, 8(8), 135–147. https://doi.org/10.37934/cfdl.15.8.135147

Nugraha, M. G., Sharfan, A., Prakoso, V. S. Y., Hidayat, M., & Saptoadi, H. (2024). Particulate matter emission in agricultural biomass residue combustion. Global Journal of Environmental Science and Management, 10(3), 1047–1066. https://doi.org/10.22034/gjesm.2024.03.08

Pandey, S., & Erbaugh, J. T. (2024). Driving sustainable uptake: a systematic review of global literature on policies governing woody biomass for energy. Discover Sustainability, 5(1). https://doi.org/10.1007/s43621-024-00205-6

Pilar González-Vázquez, M., Rubiera, F., Pevida, C., Pio, D. T., & Tarelho, L. A. C. (2021). Thermodynamic Analysis of Biomass Gasification Using Aspen Plus: Comparison of Stoichiometric and Non-Stoichiometric Models. Energies, 14(1), 189. https://doi.org/10.3390/en14010189

Siddiqui, M. Z., Sheraz, M., Toor, U. A., Anus, A., Mahmood, A., Haseeb, M., Ibrahim, M., Khoo, K. S., Devadas, V. V., Mubashir, M., Ullah, S., & Show, P. L. (2022). Recent approaches on the optimization of biomass gasification process parameters for product H2 and syngas ratio: a review. Environment, Development and Sustainability, 27(9), 22605–22633. https://doi.org/10.1007/s10668-022-02279-6

Zhakupov, D., Kulmukanova, L., Sarbassov, Y., & Shah, D. (2022). Flue gas analysis for biomass and coal co-firing in fluidized bed: process simulation and validation. International Journal of Coal Science and Technology, 9(1), 1–11. https://doi.org/10.1007/s40789-022-00531-y

Zhou, Y. (2024). Experimental and Aspen Plus modeling research on bio-char and syngas co-production by gasification of biomass waste: the products and reaction energy balance evaluation. Biomass Conversion and Biorefinery, 14(4), 5387–5398. https://doi.org/10.1007/s13399-023-04085-0

Zhu, S., Shen, J., Liu, X., Zhang, H., & Li, B. (2013). The modified model for predicting the products distribution in pyrolysis of biomass. ICMREE 2013 - Proceedings: 2013 International Conference on Materials for Renewable Energy and Environment, 1, 331–334. https://doi.org/10.1109/ICMREE.2013.6893677

Copyright (c) 2025 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.