Hybrid Ultrasound and Advanced Oxidation Process Regeneration of Spent FCC Catalysts: Optimization and Their Catalytic Performance

Downloads

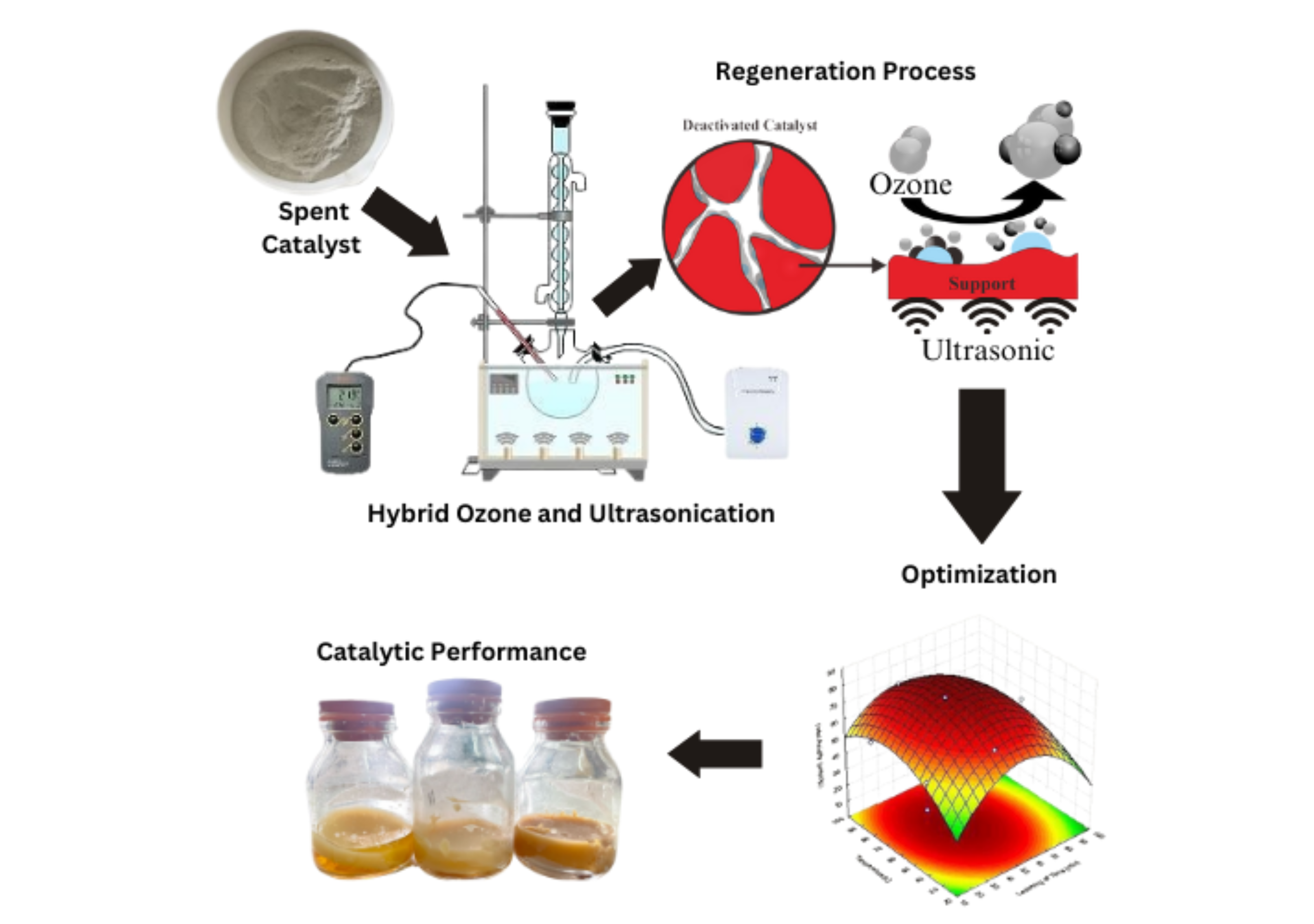

This study investigated the regeneration of spent fluid catalytic cracking (FCC) catalysts, which become inactive due to the accumulation of poisons at active sites. The objective of the study was to enhance acidity by regenerating spent FCC catalysts through ultrasonic and oxidation processes (UAOPs) and evaluate their effectiveness in synthesizing glycerol monostearate (GMS). The results demonstrate that spent FCC catalysts regenerated with UAOPs can significantly increase catalyst acidity, which plays a crucial role in GMS synthesis. The optimal conditions identified were temperature X1 (60 °C), regeneration time X2 (50 minutes), and flow rate X3 (9 L/h). This optimization was conducted using the Statistica 10 software, resulting in an optimal acidity value of 0.08460 mmol/gram. The GMS yield achieved was 25.33%, which was slightly higher than the yield reported in previous studies utilizing ZSM-5 and dealuminated Y catalysts for the synthesis of glycerol monostearate. Overall, this study suggests that spent FCC catalysts have potential applications in GMS synthesis

Anggoro, D. D., Oktavianty, H., Sasongko, S. B., & Buchori, L. (2020). Effect of dealumination on the acidity of zeolite Y and the yield of glycerol mono stearate (GMS). Chemosphere, 257, 127012. https://doi.org/10.1016/j.chemosphere.2020.127012

Anggoro, D. D., Sasongko, S. B., Buchori, L., Sulistyani, K. C., Oktavijaya, A., & Oktavianty, H. (2019). Dealumination of ZSM-5 as catalyst to convert glycerol to glycerol monostearate. IOP Conference Series: Materials Science and Engineering, 578(1), 012027. https://doi.org/10.1088/1757-899X/578/1/012027

Astuti, W., Prilitasari, N. M., Iskandar, Y., Bratakusuma, D., & Petrus, H. T. B. M. (2018). Leaching behavior of lanthanum, nickel and iron from spent catalyst using inorganic acids. IOP Conference Series: Materials Science and Engineering, 285(1), 012007. https://doi.org/10.1088/1757-899X/285/1/012007

Ben Fredj, S., Novakoski, R. T., Tizaoui, C., & Monser, L. (2017). Two-phase ozonation for the removal of estrone, 17β-estradiol and 17α-ethinylestradiol in water using ozone-loaded decamethylcyclopentasiloxane. Ozone: Science and Engineering, 39(5), 343–356. https://doi.org/10.1080/01919512.2017.1322896

Bugaev, L. A., Van Bokhoven, J. A., Sokolenko, A. P., Latokha, Y. V., & Avakyan, L. A. (2005). Local structure of aluminum in zeolite mordenite as affected by temperature. Journal of Physical Chemistry B, 109(21), 10771–10778. https://doi.org/10.1021/jp0508709

Chang, J., Zhang, E. D., Zhang, L. B., Peng, J. H., Zhou, J. W., Srinivasakannan, C., & Yang, C. J. (2017). A comparison of ultrasound-augmented and conventional leaching of silver from sintering dust using acidic thiourea. Ultrasonics Sonochemistry, 34, 222–231. https://doi.org/10.1016/j.ultsonch.2016.05.038

Da Silva-Machado, M., Cardoso, D., Prez-Pariente, J., & Sastre, E. (2000). Esterification of lauric acid with glycerol using modified zeolite beta as catalyst. Studies in Surface Science and Catalysis, 3417–3422.

Dey, A., & Gogate, P. R. (2024). Ultrasound assisted synthesis of Fe‐TiO2 and Ce‐TiO2 catalysts and subsequent application for photocatalytic, sonocatalytic, and sonophotocatalytic decolorization of basic Victoria blue dye. Environmental Quality Management, 33(4), 3–17. https://doi.org/10.1002/tqem.21970

Doyle, A. M., Albayati, T. M., Abbas, A. S., & Alismaeel, Z. T. (2016). Biodiesel production by esterification of oleic acid over zeolite Y prepared from kaolin. Renewable Energy, 97, 19–23. https://doi.org/10.1016/j.renene.2016.05.067

Fan, Y., Bao, X., Lin, X., Shi, G., & Liu, H. (2006). Acidity adjustment of HZSM-5 zeolites by dealumination and realumination with steaming and citric acid treatments. Journal of Physical Chemistry B, 110(31), 15411–15416. https://doi.org/10.1021/jp0607566

Fischer, C. H. (1986). Ultrasonic irradiation of water in the presence of 18i1s02: Isotope exchange and isotopic distribution of H202. The Journal of Physical Chemistry, 90, 1954–1956.

Gebremariam, S. N., & Marchetti, J. M. (2018). Economics of biodiesel production: Review. Energy Conversion and Management, 168, 74–84. https://doi.org/10.1016/j.enconman.2018.05.002

Gogate, P. R. (2020). Improvements in catalyst synthesis and photocatalytic oxidation processing based on the use of ultrasound. Topics in Current Chemistry, 378(2), 29. https://doi.org/10.1007/s41061-020-0293-9

Innocenzi, V., Ferella, F., de Michelis, I., & Vegliò, F. (2015). Treatment of fluid catalytic cracking spent catalysts to recover lanthanum and cerium: Comparison between selective precipitation and solvent extraction. Journal of Industrial and Engineering Chemistry, 24, 92–97. https://doi.org/10.1016/j.jiec.2014.09.014

Istadi, I., Amalia, R., Riyanto, T., Anggoro, D. D., Jongsomjit, B., & Putranto, A. B. (2022). Acids treatment for improving catalytic properties and activity of the spent RFCC catalyst for cracking of palm oil to kerosene-diesel fraction fuels. Molecular Catalysis, 527, 112420. https://doi.org/10.1016/j.mcat.2022.112420

Jiang, S., Late, E. K. Y., Jeromé, F., Amaniampong, P. N., & Mushrif, S. H. (2024). Ultrasound‐assisted catalysis: A pathway to novel and selective chemical transformations in condensed phase. ChemistrySelect, 9(35), e202401953. https://doi.org/10.1002/slct.202401953

Khataee, A. R., & Dehghan, G. (2011). Optimization of biological treatment of a dye solution by macroalgae Cladophora sp. using response surface methodology. Journal of the Taiwan Institute of Chemical Engineers, 42(1), 26–33. https://doi.org/10.1016/j.jtice.2010.03.007

Li, H., Hu, C., He, X., Wang, J., Tian, S., Zhu, X., & Mao, X. (2024). Mechanism and kinetics study of vanadium leaching from landfilled metallurgical residues by ultrasonic with ozonation enhancement in a low-acid medium. Ultrasonics Sonochemistry, 109, 106998. https://doi.org/10.1016/j.ultsonch.2024.106998

Lin, G., Cheng, S., Wang, S., Hu, T., Peng, J., Xia, H., Jiang, F., Li, S., & Zhang, L. (2018). Process optimization of spent catalyst regeneration under microwave and ultrasonic spray-assisted. Catalysis Today, 318, 191–198. https://doi.org/10.1016/j.cattod.2017.09.042

Lin, G., Hu, T., Peng, J., Yin, S., Zhang, L., Guo, W., & Liu, Y. (2016). Optimization of experiments for microwave drying of hydrometallurgy mud using response surface methodology. Arabian Journal for Science and Engineering, 41(2), 569–576. https://doi.org/10.1007/s13369-015-1687-9

Marafi, M., & Stanislaus, A. (2011). Waste catalyst utilization: Extraction of valuable metals from spent hydroprocessing catalysts by ultrasonic-assisted leaching with acids. Industrial and Engineering Chemistry Research, 50(16), 9495–9501. https://doi.org/10.1021/ie200789u

Mavukwana, A. E., Burra, K. G., Sempuga, C., Castaldi, M., & Gupta, A. K. (2024). Effect of spent fluid catalytic cracking (FCC) catalyst on syngas production from pyrolysis and CO2-assisted gasification of waste tires. Fuel, 355, 129446. https://doi.org/10.1016/j.fuel.2023.129446

Monneyron, P., Mathé, S., Manero, M. H., & Foussard, J. N. (2003). Regenaration of high silica zeolites via advanced oxidation processes: A preliminary study about adsorbent reactivity toward ozone. Chemical Engineering Research and Design, 81(9), 1193–1198. https://doi.org/10.1205/026387603770866371

Oza, R., Shah, N., & Patel, S. (2011). Recovery of nickel from spent catalysts using ultrasonication-assisted leaching. Journal of Chemical Technology and Biotechnology, 86(10), 1276–1281. https://doi.org/10.1002/jctb.2649

Pérez-Palacios, T., Petisca, C., Melo, A., & Ferreira, I. M. P. L. V. O. (2012). Quantification of furanic compounds in coated deep-fried products simulating normal preparation and consumption: Optimisation of HS-SPME analytical conditions by response surface methodology. Food Chemistry, 135(3), 1337–1343. https://doi.org/10.1016/j.foodchem.2012.05.100

Richard, R., Julcour-Lebigue, C., & Manero, M.-H. (2017). Towards a new oxidation process using ozone to regenerate coked catalysts. 39(5). https://doi.org/10.1080/01919512.2017.1326005ï

Rodríguez, E. D., Bernal, S. A., Provis, J. L., Gehman, J. D., Monzó, J. M., Payá, J., & Borrachero, M. V. (2013). Geopolymers based on spent catalyst residue from a fluid catalytic cracking (FCC) process. Fuel, 109, 493–502. https://doi.org/10.1016/j.fuel.2013.02.053

Saikia, B. J., Goswami, S. R., Borthakur, R., Roy, I. B., & Borah, R. R. (2015). Spectroscopic Characterization and Quantitative Estimation of Natural Weathering of Silicates in Sediments of Dikrong River, India. Journal of Modern Physics, 06(11), 1631–1641. https://doi.org/10.4236/jmp.2015.611164

Sumarno, Dzawilhijjah, U., Firmansyah, T. R., & Trisanti, P. N. (2019). The effect of ultrasound for impurities removal on spent catalyst from naphtha hydrotreater (NHT) processing unit. AIP Conference Proceedings, 2085. https://doi.org/10.1063/1.5095008

Sun, Y., Hu, J., An, S., Zhang, Q., Guo, Y., Song, D., & Shang, Q. (2017). Selective esterification of glycerol with acetic acid or lauric acid over rod-like carbon-based sulfonic acid functionalized ionic liquids. Fuel, 207, 136–145. https://doi.org/10.1016/j.fuel.2017.06.073

Trisunaryanti, W., Purwono, S., & Putranto, A. (2008). Catalytic hydrocracking of waste lubricant oil into liquid fuel fraction using ZnO, Nb 2 O 5 , activated natural zeolite and their modification. Indonesian Journal of Chemistry, 8(3), 342–347.

Vargas, A. M. M., Martins, A. C., & Almeida, V. C. (2012). Ternary adsorption of acid dyes onto activated carbon from flamboyant pods (Delonix regia): Analysis by derivative spectrophotometry and response surface methodology. Chemical Engineering Journal, 195–196, 173–179. https://doi.org/10.1016/j.cej.2012.04.090

Wang, B., Xiong, X., Shui, Y., Huang, Z., & Tian, K. (2019). A systematic study of enhanced ozone mass transfer for ultrasonic-assisted PTFE hollow fiber membrane aeration process. Chemical Engineering Journal, 357, 678–688. https://doi.org/10.1016/j.cej.2018.09.188

Wang, H., Li, H., Lee, C. K., Mat Nanyan, N. S., & Tay, G. S. (2024). A systematic review on utilization of biodiesel-derived crude glycerol in sustainable polymers preparation. International Journal of Biological Macromolecules, 261 (Part 1), 129536. https://doi.org/10.1016/j.ijbiomac.2024.129536

Wang, T., Le, T., Ravindra, A. V., Jue, H., Zhang, L., & Wang, S. (2021). Enhanced regeneration of spent FCC catalyst by using oxalic acid-sulfuric acid mixture under ultrasonic irradiation. Journal of Materials Research and Technology, 15, 7085–7099. https://doi.org/10.1016/j.jmrt.2021.11.126

Wei, C., Zhang, J., Zhang, Y., Zhang, G., Zhou, P., Li, W., ... Zhang, W. (2017). Ultrasound enhanced heterogeneous activation of peroxymonosulfate by a Co-NiOx catalyst. Water Science and Technology, 76(6), 1436–1446. https://doi.org/10.2166/wst.2017.316

Yang, X., Wang, S., Chen, Y., Fu, L., Liu, H., Sheng, X., Xia, H., & Zhang, L. (2024). Constructing advanced oxidation field in ultrasonic toward efficient recovery of palladium from spent catalysts. ACS Sustainable Chemistry & Engineering, 12(51), 18454–18465. https://doi.org/10.1021/acssuschemeng.4c08215

Zhang, H., Shen, Z., Gong, J., & Liu, H. (2023). Influences of regeneration atmospheres on structural transformation and renderability of fluidized catalytic cracking catalyst. Chinese Journal of Chemical Engineering, 63, 71–80. https://doi.org/10.1016/j.cjche.2023.04.020

Zhang, Q., Xia, H., Xu, Y., Jiang, G., Cai, W., & Zhang, L. (2023). Mechanism of removal of toxic arsenic (As) from zinc sulfate solution by ultrasonic enhanced neutralization with zinc roasting dust. Separation and Purification Technology, 322. https://doi.org/10.1016/j.seppur.2023.124258

Zhang, Y., Sun, G., Gao, S., & Xu, G. (2015). Regeneration kinetics of spent FCC catalyst via coke gasification in a micro fluidized bed. Procedia Engineering, 102, 1758–1765. https://doi.org/10.1016/j.proeng.2015.01.312.

Copyright (c) 2026 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.