Investigating the Impact of GGBS and FA as Partial Replacements and PVA Addition on Mechanical Properties of Cement Mortar

Downloads

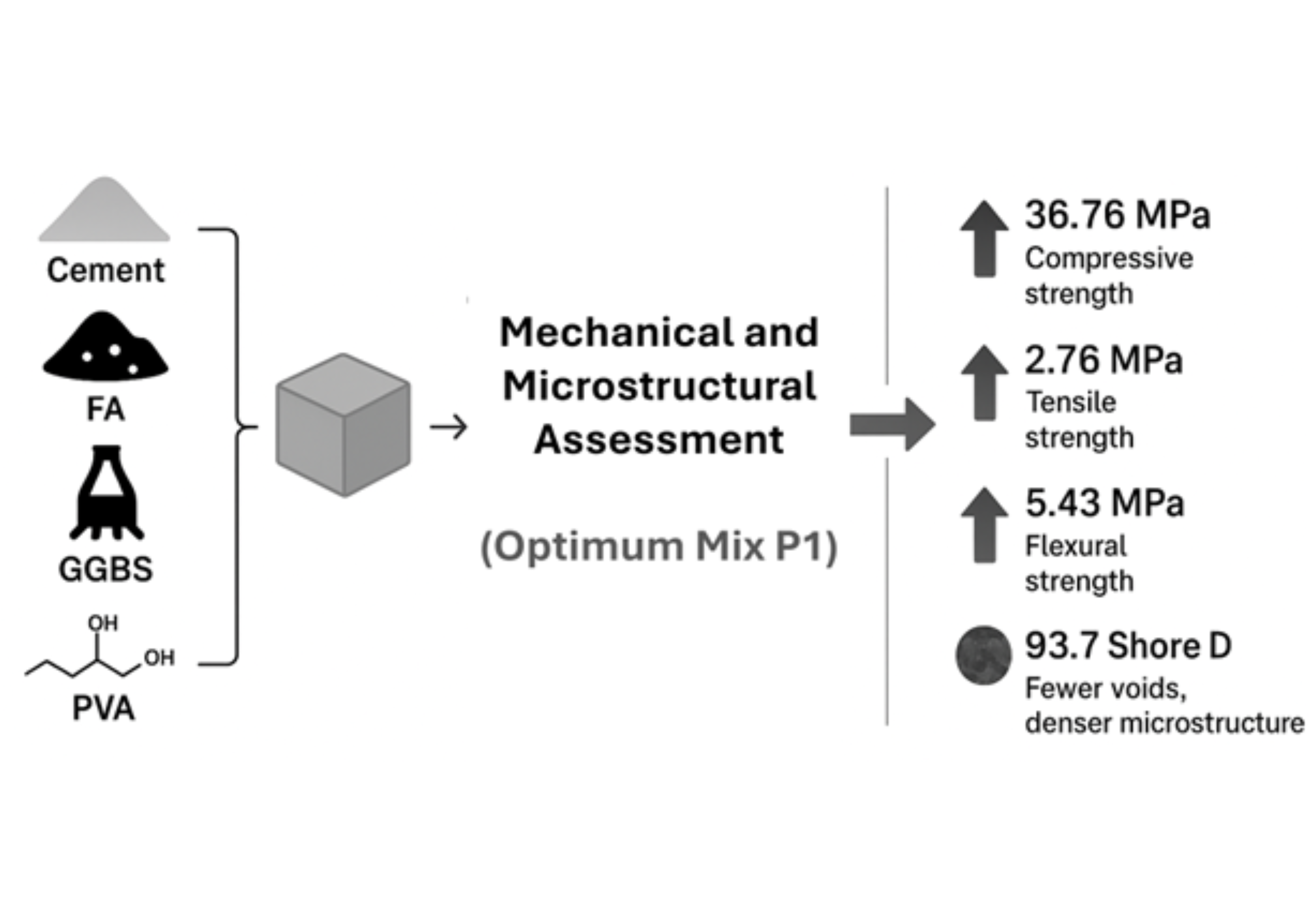

This study investigated the effects of partial cement replacement with Fly Ash (FA) and Ground Granulated Blast-furnace Slag (GGBS), as well as the addition of Polyvinyl Alcohol (PVA), on the mechanical and hardness properties of mortars. Mortar mixes were prepared with 15-30% FA (F-series), 15-30% GGBS (G-series), and varying PVA additions (P-series), and compared against a reference mix (Ref). Compressive, tensile, and flexural strengths at 28 days, along with Shore D hardness, were evaluated. Results indicated that both FA and GGBS improved 28-day compressive strength over the reference (Ref: 27.43 MPa), with optimal replacements at 20% FA (F20: 30.02 MPa) and 25% GGBS (G25: 34.12 MPa). GGBS mixes generally outperformed FA mixes across all tested properties, attributed to GGBS's higher calcium content promoting faster hydration and denser C-S-H gel formation. The addition of PVA further enhanced mechanical performance, with the P1 mix achieving the highest compressive (36.76 MPa), tensile (2.76 MPa), and flexural (5.43 MPa) strengths, likely due to PVA's film-forming and crack-bridging capabilities. However, excessive PVA addition showed diminishing returns. All modified mortars exhibited increased hardness compared to the reference, with GGBS (G30: 94.11) and PVA (P1: 93.73) mixes showing peak values. The findings highlight the effectiveness of GGBS as a supplementary cementitious material and demonstrate the significant potential of PVA modification for enhancing mortar strength characteristics, although optimal dosages are crucial.

Abbas, W. A., Gorgis, I. N., & Hussein, M. J. (2020). Modification of microstructure of cement mortars by water-soluble polyvinyl alcohol. IOP Conference Series: Materials Science and Engineering 737(1), 012057. IOP Publishing.

Abbas, W. A., Korkess, I. N., & Jasmin, H. M. (2018). Investigation of the optimal percentage from polyvinyl alcohol on flexural strength of cement mortar composite. Int J Eng Technol, 7, 584–587.

Agarwal, S. K., & Gulati, D. (2006). Utilization of industrial wastes and unprocessed micro-fillers for making cost effective mortars. Construction and Building Materials, 20(10), 999–1004.

Agnihotri, A., & Ramana, P. V. (2022). GGBS: Fly-Ash evaluation and mechanical properties within high strength concrete. Materials Today: Proceedings, 50, 2404–2410.

Ahmed, H. U., Mohammed, A. A., & Mohammed, A. (2022). Soft computing models to predict the compressive strength of GGBS/FA-geopolymer concrete. PloS one, 17(5), e0265846.

Almeida, A. E. D. S., & Sichieri, E. P. (2006). Mineralogical study of polymer modified mortar with silica fume. Construction and Building Materials, 20(10), 882–887.

Antiohos, S. K., Tapali, J. G., Zervaki, M., Sousa-Coutinho, J., Tsimas, S., & Papadakis, V. G. (2013). Low embodied energy cement containing untreated RHA: A strength development and durability study. Construction and Building Materials, 49, 455–463.

Assaad, J. J. (2018). Development and use of polymer-modified cement for adhesive and repair applications. Construction and Building Materials, 163, 139–148.

Budavari, S., O’Neil, M. J., Smith, A., & Heckelman, P. E. (1996). In; The Merck Index, 13th Edn., Merck & Co. Inc., Whitehouse Station, NJ, 948.

Cheerarot, R., Tangpagasit, J., & Jaturapitakkul, C. (2004). Compressive strength of mortars due to pozzolanic reaction of fly ash. Special Publication, 221, 411–426.

Chindaprasirt, P., Sinsiri, T., Kroehong, W., & Jaturapitakkul, C. (2014). Role of filler effect and pozzolanic reaction of biomass ashes on hydrated phase and pore size distribution of blended cement paste. Journal of Materials in Civil Engineering, 26(9), 04014057.

Fan, J., Li, G., Deng, S., & Wang, Z. (2019). Mechanical properties and microstructure of polyvinyl alcohol (PVA) modified cement mortar. Applied Sciences, 9(11), 2178.

Jamil, M., Kaish, A. B. M. A., Raman, S. N., & Zain, M. F. M. (2013). Pozzolanic contribution of rice husk ash in cementitious system. Construction and Building Materials, 47, 588–593.

Karim, M. R., Hossain, M. M., Khan, M. N. N., Zain, M. F. M., Jamil, M., & Lai, F. C. (2014). On the utilization of pozzolanic wastes as an alternative resource of cement. Materials, 7(12), 7809–7827.

Le, H. T., Kraus, M., Siewert, K., & Ludwig, H. M. (2015). Effect of macro-mesoporous rice husk ash on rheological properties of mortar formulated from self-compacting high-performance concrete. Construction and Building Materials, 80, 225–235.

Mirza, J., Mirza, M. S., & Lapointe, R. (2002). Laboratory and field performance of polymer-modified cement-based repair mortars in cold climates. Construction and Building Materials, 16(6), 365–374.

Mohammed Zidan Sameer, V., Vyshakh, C., Thomas, G.E., Sajith, A.S. (2024). Numerical Modelling and Analysis of GGBS Mortar for Predicting Strength Parameters. In: Nehdi, M., Hung, M.K., Venkataramana, K., Antony, J., Kavitha, P.E., Beena B R (eds) Proceedings of SECON’23. SECON 2023. Lecture Notes in Civil Engineering, 381, (295–300). Springer, Cham.

Ohama, Y. (1995). Handbook of Polymer-Modified Concrete and Mortars: Properties and Process Technology. Park Ridge, NJ: Noyes Publications (William Andrew).

Park, D., Ahn, J., Oh, S., Song, H., & Noguchi, T. (2009). Drying effect of polymer-modified cement for patch-repaired mortar on constraint stress. Construction and Building Materials, 23(1), 434–447.

Rashad, A. M., Seleem, H. E. D. H., & Shaheen, A. F. (2014). Effect of silica fume and slag on compressive strength and abrasion resistance of HVFA concrete. International Journal of Concrete Structures and Materials, 8, 69–81.

Sakai, E., & Sugita, J. (1995). Composite mechanism of polymer modified cement. Cement and Concrete Research, 25(1), 127–135.

Shaker, F. A., El-Dieb, A. S., & Reda, M. M. (1997). Durability of styrene-butadiene latex modified concrete. Cement and Concrete Research, 27(5), 711–720.

Shubbar, A. A., Al-Shaer, A., AlKizwini, R. S., Hashim, K., Hawesah, H. A., & Sadique, M. (2019). Investigating the influence of cement replacement by high volume of GGBS and PFA on the mechanical performance of cement mortar. IOP Conference Series: Materials Science and Engineering, 584 (1), 012022. IOP Publishing.

Shukla, A., Singh, C. K., & Sharma, A. K. (2011). Study of the properties of concrete by partial replacement of Ordinary Portland Cement by rice husk ash. International Journal of Earth Sciences and Engineering, 4(SPL 6), 965–968.

Van Tuan, N., Ye, G., Van Breugel, K., & Copuroglu, O. (2011). Hydration and microstructure of ultra-high performance concrete incorporating rice husk ash. Cement and Concrete Research, 41(11), 1104–1111.

Zain, M. F. M., Islam, M. N., Mahmud, F., & Jamil, M. (2011). Production of rice husk ash for use in concrete as a supplementary cementitious material. Construction and Building Materials, 25(2), 798–805.

Copyright (c) 2025 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.