Investigating the Role of Glycerol as a Plasticizer in Durian Rind-derived Cellulose Bioplastic

Downloads

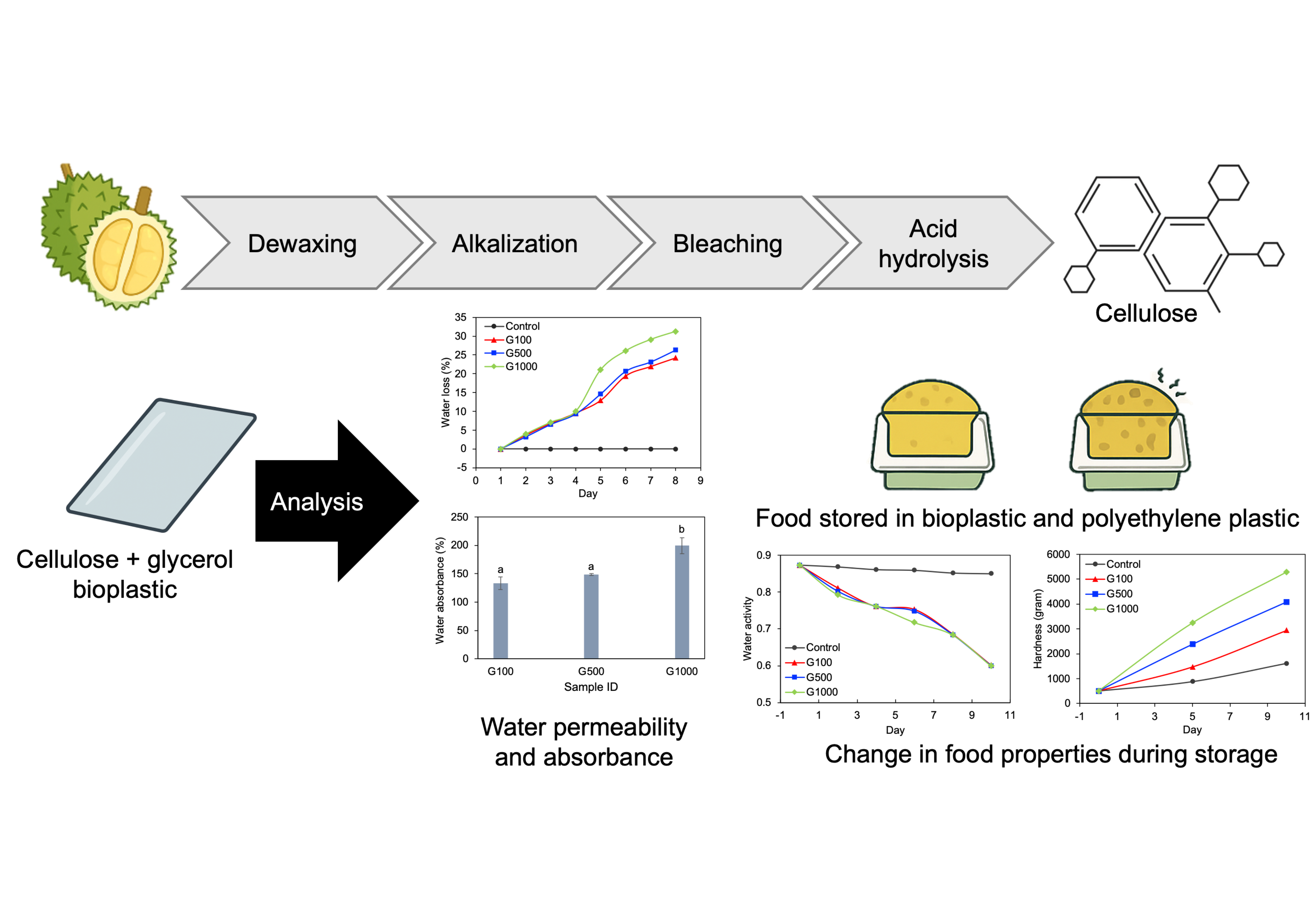

The widespread use of conventional plastic packaging poses significant environmental challenges. As a sustainable alternative, bioplastics derived from cellulose sourced from agricultural waste are gaining interest. This study explores the development of biodegradable bioplastic films derived from durian rind cellulose, with glycerol used as a plasticizer. Cellulose was isolated from durian rind using chemical extraction methods, resulting in a 29% yield with 70.2% purity. Bioplastic films were synthesized by incorporating varying amounts of glycerol into the cellulose matrix. The successful integration of cellulose and glycerol were confirmed by Fourier Transform Infrared spectroscopy. Morphology analysis revealed that increasing glycerol disrupted the dense fiber structure, leading to more flexible and visually transparent films. This was consistent with colorimetric analysis, which showed increased transparency with higher glycerol concentrations. Glycerol addition also resulted in greater water vapor permeability and water absorption, attributed to the plasticizer’s hydrophilic nature. Biodegradability tests indicated that all bioplastic samples fully degraded within 10 days in soil, with faster degradation occurring at higher glycerol levels. In food packaging trials using sponge cake as a model, the bioplastic films effectively prevented mold growth over 10 days. However, moisture loss led to a reduction in water activity and an increase in product hardness. Conversely, samples wrapped in commercial polyethylene (PE) plastic retained moisture and texture but showed significant mold growth. These findings demonstrate the potential of durian rind cellulose as a sustainable raw material for biodegradable packaging, and highlight the critical role of glycerol concentration in tailoring film properties for food applications.

Abdullah, N., Gerhauser, H., & Bridgwater, A. V. (2007). Bio-oil from fast pyrolysis of oil palm empty fruit bunches. Journal of Physical Science, 18(1), 57–74.

Abe, M. M., Martins, J. R., Sanvezzo, P. B., Macedo, J. V., Branciforti, M. C., Halley, P., Botaro, V. R., & Brienzo, M. (2021). Advantages and disadvantages of bioplastics production from starch and lignocellulosic components. Polymers, 13(15), 2484.

Abolore, R. S., Jaiswal, S., & Jaiswal, A. K. (2024). Green and sustainable pretreatment methods for cellulose extraction from lignocellulosic biomass and its applications: A review. Carbohydrate Polymer Technologies and Applications, 7, 100396.

Abral, H., Ariksa, J., Mahardika, M., Handayani, D., Aminah, I., Sandrawati, N., Pratama, A. B., Fajri, N., Sapuan, S. M., & Ilyas, R. A. (2020). Transparent and antimicrobial cellulose film from ginger nanofiber. Food Hydrocolloids, 98, 105266.

Ali, S. S., Abdelkarim, E. A., Elsamahy, T., Al-Tohamy, R., Li, F., Kornaros, M., Zuorro, A., Zhu, D., & Sun, J. (2023). Bioplastic production in terms of life cycle assessment: A state-of-the-art review. Environmental Science and Ecotechnology, 15, 100254.

Almazrouei, M., Samad, T. El, & Janajreh, I. (2017). Thermogravimetric Kinetics and High Fidelity Analysis of Crude Glycerol. Energy Procedia, 142, 1699–1705.

Aqil, M., Abderrahim, B., Abderrahman, E., Mohamed, A., Fatima, T., Abdesselam, T., & Krim, O. (2015). Kinetic Thermal Degradation of Cellulose, Polybutylene Succinate and a Green Composite: Comparative Study. World Journal of Environmental Engineering, 3(4), 95–110.

Ascencio, J. J., Chandel, A. K., Philippini, R. R., & da Silva, S. S. (2020). Comparative study of cellulosic sugars production from sugarcane bagasse after dilute nitric acid, dilute sodium hydroxide and sequential nitric acid-sodium hydroxide pretreatment. Biomass Conversion and Biorefinery, 10(4), 813–822.

Benitez, J. J., Florido-Moreno, P., Porras-Vázquez, J. M., Tedeschi, G., Athanassiou, A., Heredia-Guerrero, J. A., & Guzman-Puyol, S. (2024). Transparent, plasticized cellulose-glycerol bioplastics for food packaging applications. International Journal of Biological Macromolecules, 273, 132956.

Castelló, M. L., Dweck, J., & Aranda, D. A. G. (2009). Thermal stability and water content determination of glycerol by thermogravimetry. Journal of Thermal Analysis and Calorimetry, 97(2), 627–630.

Damayanti, A., Wulansarie, R., Bahlawan, Z. A. S., Suharta, Royana, M., Basuki, M. W. N. M., Nugroho, B., & Andri, A. L. (2023). Effects of Phosphate and Thermal Treatments on the Characteristics of Activated Carbon Manufactured from Durian (Durio zibethinus) Peel. ChemEngineering, 7, 75.

Danish, M., Umer Rashid, T., Mai Sci, C. J., Waseem Mumtaz, M., Fakhar, M., & Rashid, U. (2016). Response Surface Methodology: An Imperative Tool for the Optimized Purification of the Residual Glycerol from Biodiesel Production Process. Chiang Mai Journal of Science, 43, 1-13.

Fauziyah, S. N., Mubarak, A. S., & Pujiastuti, D. Y. (2021). Application of glycerol on bioplastic based carrageenan waste cellulose on biodegradability and mechanical properties bioplastic. IOP Conference Series: Earth and Environmental Science, 679, 012005.

Gravelle, A. J., Blach, C., Weiss, J., Barbut, S., & Marangoni, A. G. (2017). Structure and properties of an ethylcellulose and stearyl alcohol/stearic acid (EC/SO:SA) hybrid oleogelator system. European Journal of Lipid Science and Technology, 119, 1700069.

Hasan, M. M., Shenashen, M. A., Hasan, M. N., Znad, H., Salman, M. S., & Awual, M. R. (2021). Natural biodegradable polymeric bioadsorbents for efficient cationic dye encapsulation from wastewater. Journal of Molecular Liquids, 323, 114587.

Huri, D., & Nisa, F. C. (2014). The Effect of Glycerol and Apple Peel Waste Extract Concentration on Physical and Chemical Characteristic of Edible Film. Jurnal Pangan Dan Agroindustri, 2(4), 29–40.

Jha, P. (2020). Effect of plasticizer and antimicrobial agents on functional properties of bionanocomposite films based on corn starch-chitosan for food packaging applications. International Journal of Biological Macromolecules, 160, 571–582.

Jie, X., Lin, C., Qian, C., He, G., Feng, Y., & Yin, X. (2024). Preparation and properties of thermoplastic starch under the synergism of ultrasonic and elongational rheology. International Journal of Biological Macromolecules, 274, 133155.

Kan, M., & Miller, S. A. (2022). Environmental impacts of plastic packaging of food products. Resources, Conservation and Recycling, 180, 106156.

Khotsaeng, N., Simchuer, W., Imsombut, T., & Srihanam, P. (2023). Effect of Glycerol Concentrations on the Characteristics of Cellulose Films from Cattail (Typha angustifolia L.) Flowers. Polymers, 15, 4535.

Liu, Y., Ahmed, S., Sameen, D. E., Wang, Y., Lu, R., Dai, J., Li, S., & Qin, W. (2021). A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends in Food Science and Technology, 112, 532–546.

Marichelvam, Manimaran, Khan, A., Geetha, Kandakodeeswaran, Abduljabbar, A. H., Syafri, E., Wazzan, M. A., Wazzan, H., & Khan, W. (2023). Development and Characterization of Sustainable Bioplastic Films Using Cellulose Extracted from Prosopis juliflora. Journal of Natural Fibers, 20, 2231271.

Masrol, S. R., Ibrahim, M. H. I., & Adnan, S. (2015). Chemi-mechanical Pulping of Durian Rinds. Procedia Manufacturing, 2, 171–180.

Moreira, R., Rebelo, R. C., Coelho, J. F. J., & Serra, A. C. (2024). Novel thermally regenerated flexible cellulose-based films. European Journal of Wood and Wood Products, 82, 1813–1826.

Niskanen, I., Zhang, K., Karzarjeddi, M., Liimatainen, H., Shibata, S., Hagen, N., Heikkilä, R., Yoda, H., & Otani, Y. (2022). Optical Properties of Cellulose Nanofibre Films at High Temperatures. Journal of Polymer Research, 29, 187.

Oblitas, R., Quispe-Sanchez, L., Guadalupe, G., Diaz, E. H., Oliva, S., Diaz-Valderrama, J. R., Yoplac, I., Valencia-Sullca, C., & Chavez, S. G. (2025). Physicochemical properties of bioactive bioplastics based on cellulose from coffee and cocoa by-products. Results in Chemistry, 15, 102201.

Paudel, S., Regmi, S., & Janaswamy, S. (2023). Effect of glycerol and sorbitol on cellulose-based biodegradable films. Food Packaging and Shelf Life, 37, 101090.

Priyadarshi, R., & Rhim, J. W. (2020). Chitosan-based biodegradable functional films for food packaging applications. Innovative Food Science and Emerging Technologies, 62, 102346.

Rajamani, A., & Lim, K. M. (2024, May 2). Taking plastics full circle: Creating a sustainable future in Indonesia. The Jakarta Post.

Rowell, R. M. (2012). Handbook of Wood Chemistry and Wood Composites, Second Edition. CRC Press.

Rumi, S. S., Liyanage, S., & Abidi, N. (2024). Soil burial-induced degradation of cellulose films in a moisture-controlled environment. Scientific Reports, 14, 6921.

Sanyang, M. L., Sapuan, S. M., Jawaid, M., Ishak, M. R., & Sahari, J. (2016). Effect of plasticizer type and concentration on physical properties of biodegradable films based on sugar palm (arenga pinnata) starch for food packaging. Journal of Food Science and Technology, 53, 326–336.

Sirviö, J. A., Visanko, M., Ukkola, J., & Liimatainen, H. (2018). Effect of plasticizers on the mechanical and thermomechanical properties of cellulose-based biocomposite films. Industrial Crops and Products, 122, 513–521.

Soltani, M., Alimardani, R., Mobli, H., & Mohtasebi, S. S. (2015). Modified Atmosphere Packaging; A Progressive Technology for Shelf-Life Extension of Fruits and Vegetables. Journal of Applied Packaging Research, 7, 33-59.

Steven, S., Fauza, A. N., Mardiyati, Y., Santosa, S. P., & Shoimah, S. M. (2022). Facile Preparation of Cellulose Bioplastic from Cladophora sp. Algae via Hydrogel Method. Polymers, 14, 4699.

Surhaini, Indriyani, & Affandi. (2023). The Effect of Glycerol Concentration on The Characteristics of Edible Film of Kimpul Starch (Xanthosoma sagittifolium). Journal of Bio & Geo Material and Energy, 3, 68-80.

Susanti, A., Kusuma, H. S., Zafira, D. K., Ilmi, A. B., Agustina, I. E., & Prayoga, L. B. A. (2021). Fabrication and Characterization of Biodegradable Plastic Based on Mixture of Starch and Cellulose from Corn Waste. Eksergi, 18, 49.

Teixeira, S. C., Silva, R. R. A., de Oliveira, T. V., Stringheta, P. C., Pinto, M. R. M. R., & Soares, N. de F. F. (2021). Glycerol and triethyl citrate plasticizer effects on molecular, thermal, mechanical, and barrier properties of cellulose acetate films. Food Bioscience, 42, 101202.

Wang, S., Lu, A., & Zhang, L. (2016). Recent advances in regenerated cellulose materials. Progress in Polymer Science, 53, 169–206.

Yasmeen, S., Kabiraz, M., Saha, B., Qadir, Md., Gafur, Md., & Masum, S. (2016). Chromium (VI) Ions Removal from Tannery Effluent using Chitosan-Microcrystalline Cellulose Composite as Adsorbent. International Research Journal of Pure and Applied Chemistry, 10(4), 1–14.

Yeng, L. C., Wahit, M. U., & Othman, N. (2015). Thermal and flexural properties of regenerated cellulose(RC)/poly(3- hydroxybutyrate)(PHB)biocomposites. Jurnal Teknologi, 75(11), 107–112.

Zhao, G., Lyu, X., Lee, J., Cui, X., & Chen, W. N. (2019). Biodegradable and transparent cellulose film prepared eco-friendly from durian rind for packaging application. Food Packaging and Shelf Life, 21, 100345.

Copyright (c) 2026 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.