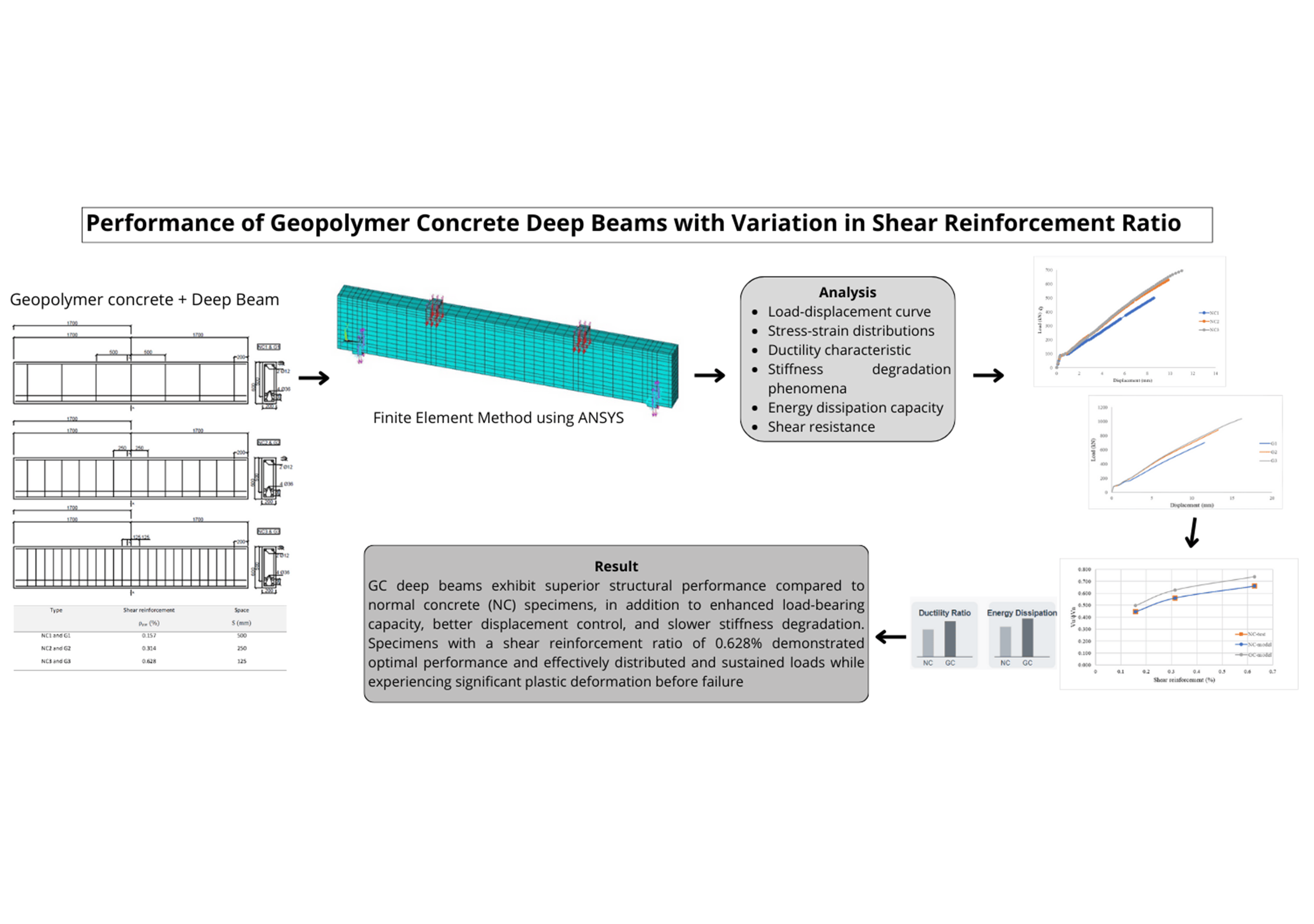

Performance of Geopolymer Concrete Deep Beams with Variation in Shear Reinforcement Ratio

Downloads

The construction industry's demand for sustainable alternatives to Portland cement has prompted investigation into geopolymer concrete (GC) as a replacement for normal concrete (NC) in deep beam applications, where structural behavior with varying shear reinforcement ratios remains insufficiently understood. This study examines the structural performance of GC and NC deep beams under monotonic loading through experimental testing and numerical modeling of six specimens—three NC (NC1, NC2, NC3) and three GC (G1, G2, G3)—with shear reinforcement ratios of 0.157%, 0.314%, and 0.628%, using LVDT sensors for displacement measurement and finite element analysis for stress–displacement validation. Results show that GC beams achieved higher maximum loads (700–1038 kN) than NC beams (500–742 kN), supported by superior compressive strength (68.36 MPa vs 43.6 MPa), greater energy dissipation (2897.54–7212.62 kN·mm vs 1340.96–2513.86 kN·mm), and improved shear capacity (ratio 0.74 vs 0.66). Ductility ratios ranged from 3.07–4.65 for NC and 1.62–2.10 for GC specimens. The enhanced performance of GC is attributed to its higher material strength, both materials exhibited similar stress distributions aligned with the strut-and-tie model and compression-controlled failure via diagonal strut formation between the loading points and supports. This study concludes GC offers strong potential as sustainable deep-beam material, achieving 40–48% higher maximum loads while maintaining comparable deflection behavior, with optimal performance at a shear reinforcement ratio of 0.628%. Experimental numerical differences remained below 1.5%. Future work should address long-term durability under cyclic loading and optimization of bond performance between GC and reinforcement materials.

Abbood, S. (2023). Strut-and-tie model and its applications in reinforced concrete deep beams: A comprehensive review. Case Studies in Construction Materials, 19, e02643. https://doi.org/10.1016/j.cscm.2023.e02643

American Concrete Institute. (2022). Building code requirements for structural concrete and commentary (ACI 318-19). ACI.

Arlan, M., Saloma, Nurjannah, S. A., Usman, A. P., Saggaff, A., Juliantina, I., & Ilmiaty, R. S. (2024). Behavior of beam-column joint self-compacting concrete (SCC) using steel fiber 5D under lateral cyclic loading. Civil Engineering and Architecture, 12(5), 3562–3570. https://doi.org/10.13189/cea.2024.120531

ASTM C78-02. (2016). Standard test method for flexural strength of concrete (using simple beam with third-point loading). ASTM International.

Badshah, M., Badshah, S., & Jan, S. (2020). Comparison of computational fluid dynamics and fluid structure interaction models for the performance prediction of tidal current turbines. Journal of Ocean Engineering and Science, 5, 164–172. https://doi.org/10.1016/j.joes.2019.10.001

Danish, A., Ozbakkaloglu, T., Mosaberpanah, M. A., Salim, M. U., Bayram, M., Yeon, J. H., & Jafar, K. (2022). Sustainability benefits and commercialization challenges and strategies of geopolymer concrete: A review. Journal of Building Engineering, 58, 105005. https://doi.org/10.1016/j.jobe.2022.105005

Decanini, L., Liberatore, L., Mollaioli, F., & De Sortis, A. (2005). Estimation of near-source ground motion and seismic behavior of RC framed structures damaged by the 1999 Athens earthquake. Journal of Earthquake Engineering, 9(5), 609–635. https://doi.org/10.1080/13632460509350559

Eltantawi, I., Sheikh, M., & Hadi, M. (2024). Design of a novel ternary blended self-compacting ultra-high-performance geopolymer concrete. Construction and Building Materials, 451, 138819. https://doi.org/10.1016/j.conbuildmat.2024.138819

Eric, Saloma, Usman, A. P., Saggaff, A., Hashim, M. F. A., & Usman, F. (2024). Behavior of exterior beam-column joints steel fiber reinforced self-compacting concrete (SFRSCC) against cyclic lateral loads. Civil Engineering and Architecture, 12(3A), 2043–2056. https://doi.org/10.13189/cea.2024.121309

Fayyad, T. M., & Lees, J. M. (2017). Experimental investigation of crack propagation and crack branching in lightly reinforced concrete beams using digital image correlation. Engineering Fracture Mechanics, 182, 487–505. https://doi.org/10.1016/j.engfracmech.2017.04.051Federal Emergency Management Agency. (2000). FEMA 356, Prestandard and commentary for the seismic rehabilitation of buildings, Washington DC.

Federal Emergency Management Agency. (2000). FEMA 356: Prestandard and commentary for the seismic rehabilitation of buildings. FEMA.

Feng, Y., Xue, Z., Zhong, H., Zhang, B., Yang, J., & Xie, J. (2024). Improving geopolymer concrete performance with hazardous solid waste phosphogypsum. Journal of Building Engineering, 95, 110333. https://doi.org/10.1016/j.jobe.2024.110333

Feng, Y., Xue, Z., Zhang, B., Xie, J., Chen, C., Tan, J., & Zhao, C. (2023). Effects of phosphogypsum substitution on the performance of ground granulated blast furnace slag/fly ash-based alkali-activated binders. Journal of Building Engineering, 70, 106387. https://doi.org/10.1016/j.jobe.2023.106387

Hamoda, A., Ghalla, M., Yehia, S. A., Ahmed, M., Abadel, A. A., Baktheer, A., & Shahin, R. I. (2024). Experimental and numerical investigations of the shear performance of reinforced concrete deep beams strengthened with hybrid SHCC–mesh. Case Studies in Construction Materials, 21, e03495. https://doi.org/10.1016/j.cscm.2024.e03495

Hamoda, A., Yehia, S. A., Ahmed, M., Abadel, A. A., Baktheer, A., & Shahin, R. I. (2024). Experimental and numerical analysis of deep beams with openings strengthened with galvanized corrugated and flat steel sheets. Case Studies in Construction Materials, 21, e03522. https://doi.org/10.1016/j.cscm.2024.e03522

Harsha, G., Sri, & Poluraju, P. (2021). Modified strut and tie method and truss reinforcement for shear strengthening of reinforced concrete deep beams. International Journal of Technology, 12, 65–77. https://doi.org/10.14716/ijtech.v12i1.3920

Indriyantho, B. R., Prasetya, B. H., Hidayat, B. A., Prasetya, H. P., Han, A. L., & Kaliske, M. (2025). Tensile behavior of self-compacting geopolymer concrete considering tension stiffening. Journal of Building Engineering, 105, 112402. https://doi.org/10.1016/j.jobe.2025.112402

Jin, L., Zhang, J., Song, B., Li, D., Li, P., & Du, X. (2023). Effect of stirrups on shear performance of geometrically similar reinforced concrete deep beams: An experimental study. Engineering Structures, 295, 116883. https://doi.org/10.1016/j.engstruct.2023.116883

Karthik, S., Mohan, K., Murali, G., Abid, S., & Dixit, S. (2024). Impact of various fibers on mode I, III and I/III fracture toughness in slag, fly ash, and silica fume-based geopolymer concrete using edge-notched disc bend specimen. Theoretical and Applied Fracture Mechanics, 134, 104751. https://doi.org/10.1016/j.tafmec.2024.104751

Kishore, K. (2023). Geopolymer concrete and its strength influencing variables. Materials Today: Proceedings, 80, 1434–1441. https://doi.org/10.1016/j.matpr.2023.01.225

Li, K., Zou, Z., Zhang, Y., & Shuai, C. (2024). Assessing the spatial-temporal environmental efficiency of global construction sector. Science of the Total Environment, 951, 175604. https://doi.org/10.1016/j.scitotenv.2024.175604

Manharawy, M. S., Mahmoud, A. A., El-Mahdy, O. O., & El-Diasity, M. H. (2022). Experimental and numerical investigation of lightweight foamed reinforced concrete deep beams with steel fibers. Engineering Structures, 260, 114202. https://doi.org/10.1016/j.engstruct.2022.114202

Manzoor, T., Bhat, J. A., & Shah, A. (2024). Performance of geopolymer concrete at elevated temperature: A critical review. Construction and Building Materials, 420, 135578. https://doi.org/10.1016/j.conbuildmat.2024.135578

Marathe, S., Sadowski, Ł., & Shree, N. (2024). Geopolymer and alkali-activated permeable concrete pavements: Bibliometrics and systematic current state of the art review, applications, and perspectives. Construction and Building Materials, 421, 135586. https://doi.org/10.1016/j.conbuildmat.2024.135586

Masoud, L., Hammoud, A., Mortada, Y., & Masad, E. (2024). Rheological, mechanical, and microscopic properties of polypropylene fiber-reinforced geopolymer concrete for additive manufacturing. Construction and Building Materials, 38, 137069. https://doi.org/10.1016/j.conbuildmat.2024.137069

Nurjannah, S. A., Usman, A. P., Saloma, & Shafa, G. Z. (2024). Numerical analysis of self-compacting concrete deep beams performance with various spaces of transverse reinforcement. Civil Engineering and Architecture, 12(6), 3839–3855. https://doi.org/10.13189/cea.2024.120608

Nurjannah, S. A., Saloma, Usman, A. P., & Wibowo, M. L. P. P. (2022). A numerical study of the comparison of normal concrete and lightweight concrete exterior beam-column joints behavior to cyclic lateral loads. Journal of Applied Engineering Science, 20(3), 765–777. https://doi.org/10.5937/jaes0-36140

Nurjannah, S. A., Saloma, Yulindasari, Aminuddin, K. M., & Chuhairy, G. (2022). The analysis of numerical self-compacting concrete wall panel models with variations of shear reinforcement. Engineering Solid Mechanics, 11, 89–102. https://doi.org/10.5267/j.esm.2022.8.002

Orhan, T. Y., Karakoç, M. B., & Ozcan, A. (2023). Durability characteristics of slag-based geopolymer concrete modified with crumb rubber. Construction and Building Materials, 404, 132851. https://doi.org/10.1016/j.conbuildmat.2023.132851

Purwanto, P., Ekaputri, J. J., Nuroji, B. R. I., Gan, B. S., & Han, A. L. (2023). Geopolymer haunch beam–column connection behavior. Arabian Journal for Science and Engineering, 48, 13633–13648. https://doi.org/10.1007/s13369-023-07921-7

Purwanto, P., Ekaputri, J. J., Nuroji, Indriyantho, B. R., Han, A., & Gan, B. S. (2022). Shear-bond behavior of self-compacting geopolymer concrete to conventional concrete. Construction and Building Materials, 321, 126167. https://doi.org/10.1016/j.conbuildmat.2021.126167

Purwanto, P., Ekaputri, J. J., Nuroji, Indriyantho, B. R., Han, A., & Gan, B. S. (2022). Mix design formulation and stress–strain relationship of geopolymer concrete. Construction and Building Materials, 318, 126095. https://doi.org/10.1016/j.conbuildmat.2021.126095

Rifkah, Saloma, & Nurjannah, S. A. (2025). Compressive and tensile strength of fly ash-based lightweight geopolymer concrete with variation of Na₂SiO₃ and NaOH using expanded polystyrene. Research on Engineering Structures & Materials. http://dx.doi.org/10.17515/resm2025-734me0308rs (Published online first)

Saloma, Hanafiah, Elysandi, D., & Meykan, D. (2017). Effect of Na₂SiO₃/NaOH on mechanical properties and microstructure of geopolymer mortar using fly ash and rice husk ash as precursor. AIP Conference Proceedings, 1903, 05013. https://doi.org/10.1063/1.5011552

Saloma, Nurjannah, S. A., Usman, A. P., Aminuddin, K. M., Iqbal, M. M., & Rifkah. (2024). Shear capacity of geopolymer concrete deep beams with variation of transverse reinforcement ratio. Civil Engineering and Architecture, 12(1), 293–311. https://doi.org/10.13189/cea.2024.120123

Shyamala, G. (2022). Impact of reinforcement and geometry of deep beam: Research perspective. Materials Today: Proceedings, 68, 1556–1561. https://doi.org/10.1016/j.matpr.2022.07.189

Swathi, & Vidjeapriya, R. (2023). Influence of precursor materials and molar ratios on normal, high, and ultra-high performance geopolymer concrete: A state-of-the-art review. Construction and Building Materials, 392, 132006. https://doi.org/10.1016/j.conbuildmat.2023.132006

Tayeh, A., Zeyad, A. M., Agwa, I. S., & Amin, M. (2021). Effect of elevated temperatures on the mechanical properties of lightweight geopolymer concrete. Case Studies in Construction Materials, 15, e00673. https://doi.org/10.1016/j.cscm.2021.e00673

Thomas, B. S., Yang, J., Bahurudeen, A., Chinnu, S. N., Abdalla, J. A., Hawileh, R. A., & Hamada, H. M. (2022). Geopolymer concrete incorporating recycled aggregates: A comprehensive review. Cleaner Materials, 3, 100056. https://doi.org/10.1016/j.clema.2022.100056

Thompson, M. K., & Thompson, J. M. (2017). ANSYS mechanical APDL for finite element analysis. Butterworth-Heinemann.

Toth, Z., & Volt, J. (2021). Whole-life carbon: Challenges and solutions for highly efficient and climate-neutral buildings. Buildings Performance Institute Europe.

Wu, H., Zhuang, X., Zhang, W., & Zhao, Z. (2022). Anisotropic ductile fracture: Experiments, modeling, and numerical simulations. Journal of Materials Research and Technology, 20, 833–856. https://doi.org/10.1016/j.jmrt.2022.07.128

Zhang, B. (2024). Durability of low-carbon geopolymer concrete: A critical review. Sustainable Materials and Technologies, 40, e00882. https://doi.org/10.1016/j.susmat.2024.e00882

Zhang, H., Chen, Y., Chen, H., Xiao, Q., & Xu, W. (2022). Experimental investigation and simulation on load-transfer paths in optimally designed RC deep beams. Engineering Structures, 278, 115469. https://doi.org/10.1016/j.engstruct.2022.115469

Zhang, J., Li, S. S., Xie, W., & Guo, Y. D. (2020). Experimental study on shear capacity of high-strength reinforced concrete deep beams with small shear span–depth ratio. Materials, 13, 1218. https://doi.org/10.3390/ma13051218

Zhao, J., Wang, S., Wang, Z., Wang, K., & Fu, C. (2023). Bond performance between FRP bars and geopolymer concrete after elevated temperature exposure. Construction and Building Materials, 384, 131476. https://doi.org/10.1016/j.conbuildmat.2023.131476

Zheng, K., Zhou, S., Zhang, Y., Wei, Y., Wang, J., Wang, Y., & Qin, X. (2023). Simplified evaluation of shear stiffness degradation of diagonally cracked reinforced concrete beams. Materials, 16(13). https://doi.org/10.3390/ma16134752

Zhou, F., Fang, J., Jiang, Z., Shi, C., Liu, Y., Zhang, Z., & Qin, B. (2024). Investigation on torsional behavior of geopolymer concrete members. Journal of Building Engineering, 92, 109708. https://doi.org/10.1016/j.jobe.2024.109708

Zhong, H., Fu, H., Feng, Y., Li, L., Zhang, B., Chen, Z., Lu, Z., & Xie, J. (2024). Compressive behaviors of high-strength geopolymeric concretes: The role of recycled fine aggregate. Buildings, 14, 1097. https://doi.org/10.3390/buildings14041097

Copyright (c) 2025 Journal of Engineering and Technological Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.